VESPA

Vibrational Spectrometer

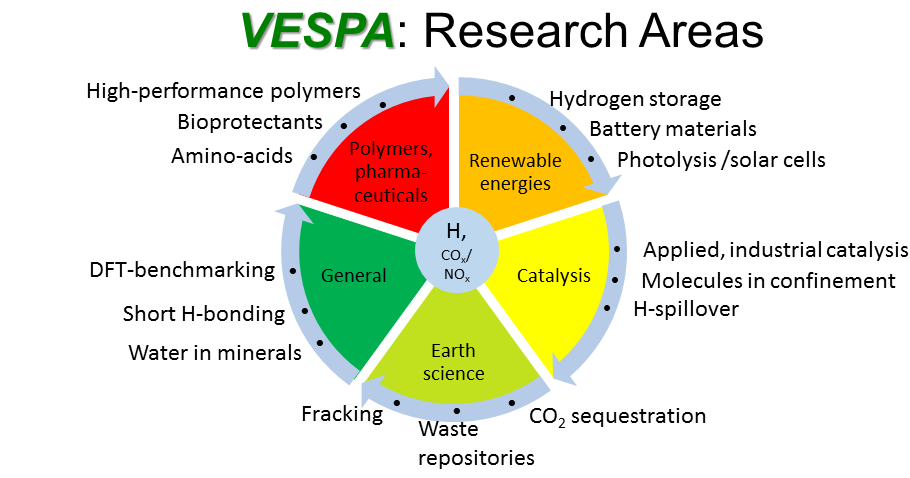

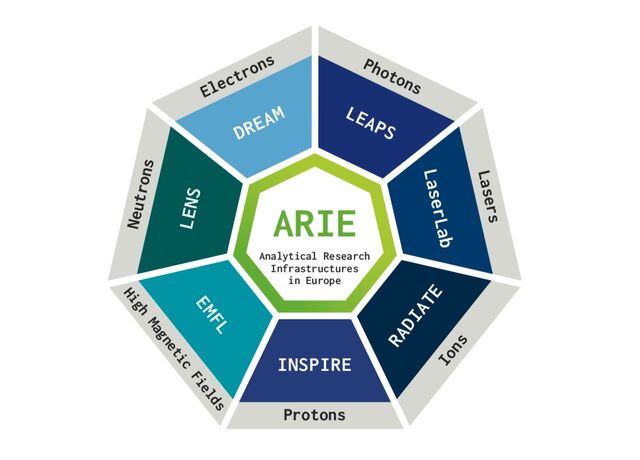

VESPA is a neutron vibrational spectrometer, and as such it will be used in an extremely wide range of chemistry, physics and materials science as well as their applications . VESPA will access scientific domains out of reach for the other ESS instruments. A thermal instrument such as a vibrational spectrometer may seem an illogical choice to present to a neutron facility that is optimized for cold neutrons. However, the ESS brilliance into the thermal range is sufficient to easily match the leading neutron vibrational spectrometers in intensity and resolution in the so-called “fingerprint region” (60-220 meV), a range most important to identify functional groups. This represents a huge scientific opportunity for the ESS especially in the area of in situ measurements for catalysis and renewable energies not only for basic but also for applied scientific research.

Instrument Class

Beam Port

Lead Scientist

Lead Engineer

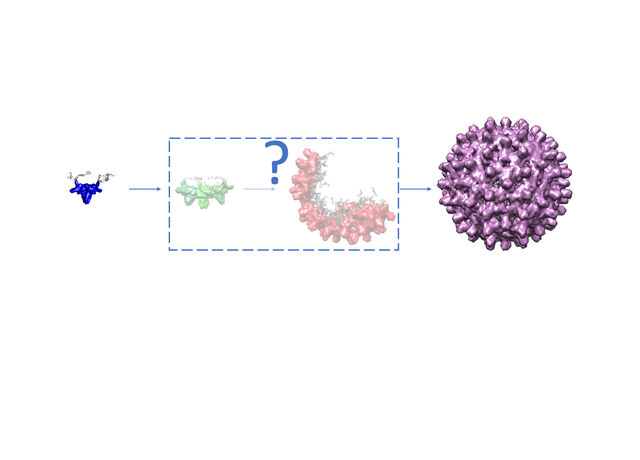

The fundamental idea behind the so-called neutron vibrational spectroscopy [1] (NVS) technique is analogous to that exploited in optical spectroscopy [2] (IR and Raman): a sampling probe, carrying energy larger than that of the internal excitations, is directed at the sample.

The resulting neutron energy loss upon excitation of a vibrational mode gives direct information on the vibrational energy level structure of the sample. In general, vibrational spectroscopy [3] is a fundamental technique used constantly in educational, research, and industrial laboratories all over the world. Its applications in the investigation of solids and liquids, soft matter, complex fluids, and biomaterials are well-known. Indeed, it has become an essential tool in medical applications, forensics, environmental compliance, and quality control to cite but a few common uses.

Fundamentally, vibrational spectroscopy probes potential energy surfaces and interatomic interactions. Alone or in combination with other techniques, vibrational spectroscopy permits the identification of bonds and functional groups, as well as the transformations that occur when bonds are broken and made in chemical reactions (e.g., in catalysis or thermal decomposition). The vibrational density of states is of great interest in itself, being related to various thermodynamic properties such as specific heat or entropy. The vibrational spectrum is affected by configurational changes in molecules thereby also providing structural information.

NVS exploits the large incoherent scattering cross section of the hydrogen nucleus. Proton dynamics or vibrations connected to the movement of H atoms can be easily detected spectroscopically, even if hydrogen is dissolved at very low concentrations in materials composed mostly of heavier atoms. For this reason, the technique attracts a high interest in the scientific community operating in the fields of chemistry, materials science, physics, and biology, with a particular emphasis on applications.

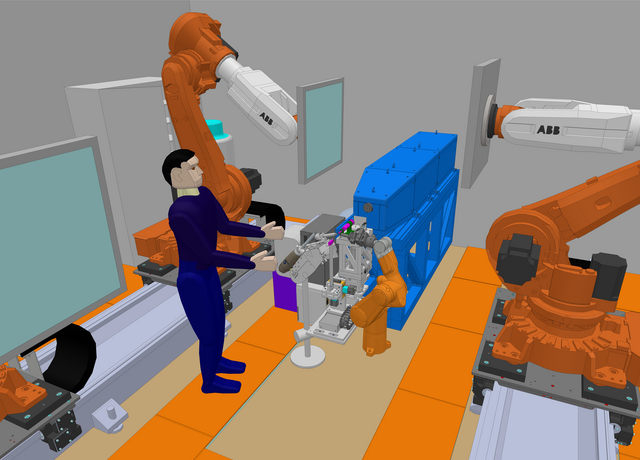

The VESPA spectrometer can be conceptually divided into the following functional blocks:

- Neutron optics system

- Chopper system

- Analyzers, filters, and detectors

- Shielding

- Shutters

- End-station

- Beam stop

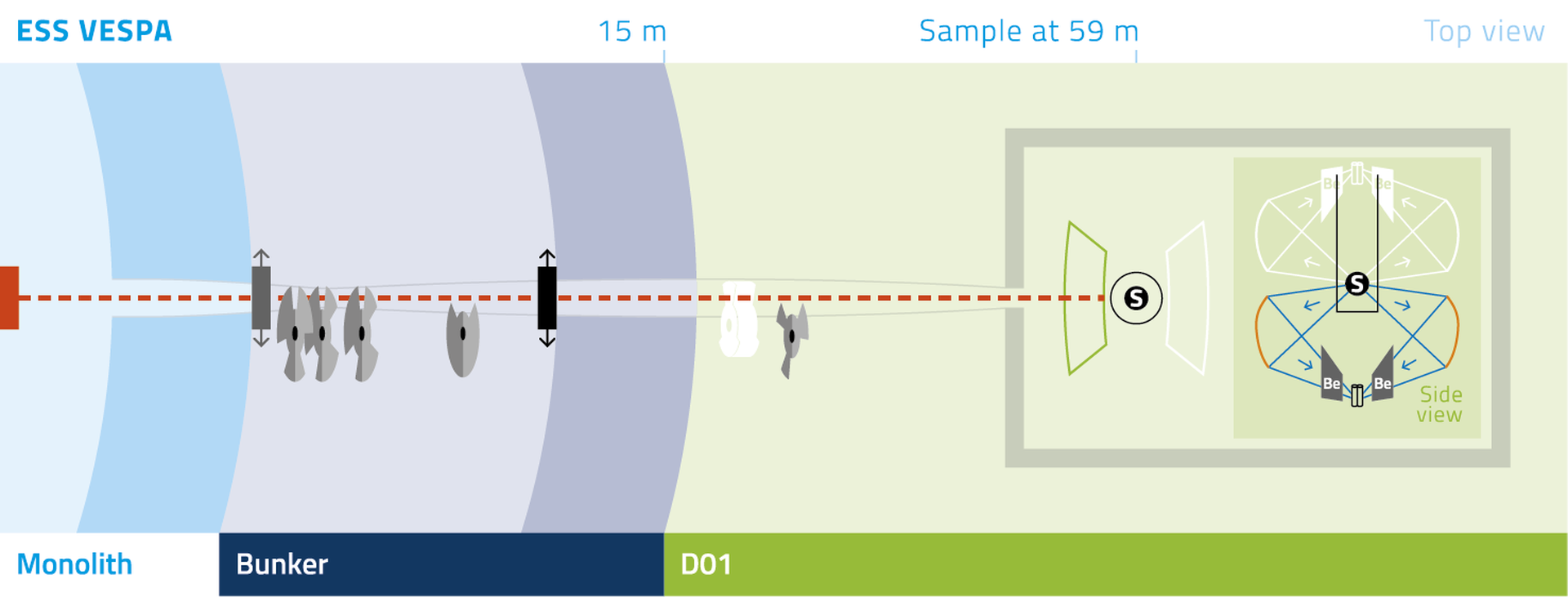

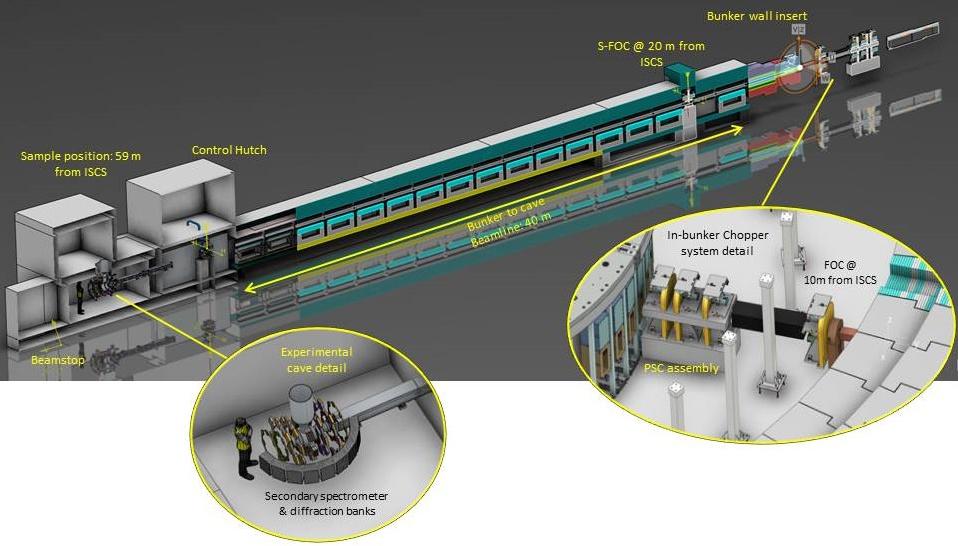

However, given the introductory character of the present explanation, we are going to deal only with the three main parts, also reported in Fig. 2.

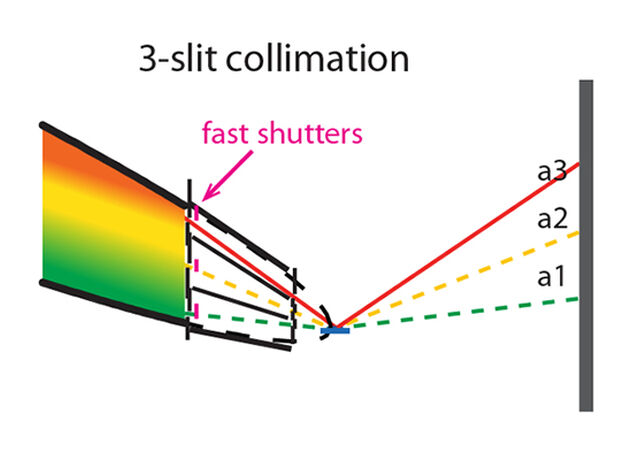

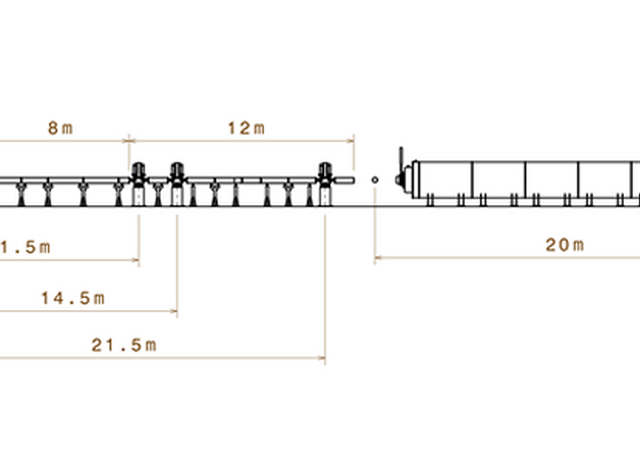

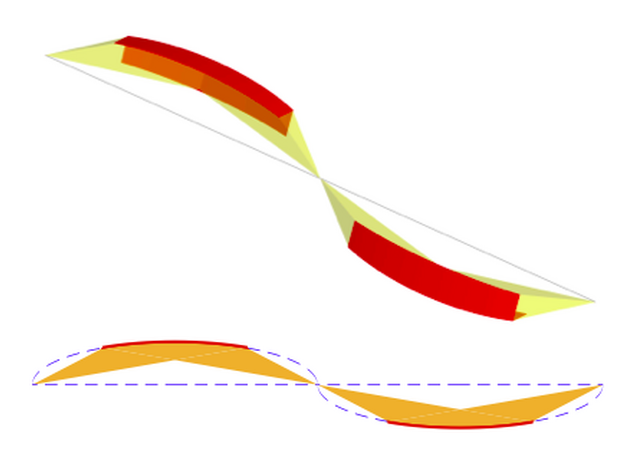

The VESPA neutron optics system will be able to perform an efficient transport of a large spectral bandwidth (0.4 Å<l<4.7 Å) in order to give rise to a homogeneously illuminated sample area (35´35 mm2, angular divergence better than 2o) at 59 m. The neutron guide will stretch from 2.00 m to 58.50 m (i.e. up to 0.50 m upstream the sample area) close to the target-to-sample centre line. In the VESPA layout the guide is planned so as to allow a direct line of sight between moderator and sample. Approximately the first 3.5 m of the guide (i.e. the “feeder”) will be inserted in the monolith, followed downstream by about 2 m of straight guide crossing the chopper area (see below). After that, a straight tapered guide (with m=4) of about 51 m will transport neutrons up to the end of the optical system. So, in total, the full guide length will be of about 56.50 m. Another part of the optical system will be a set of jaws (horizontal and vertical) in order to define the beam size before the sample.

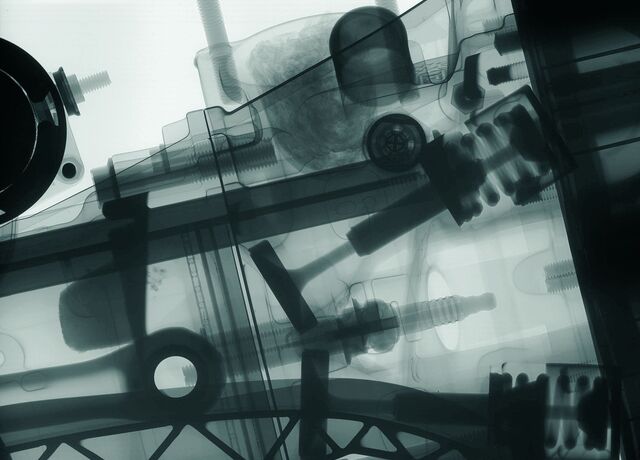

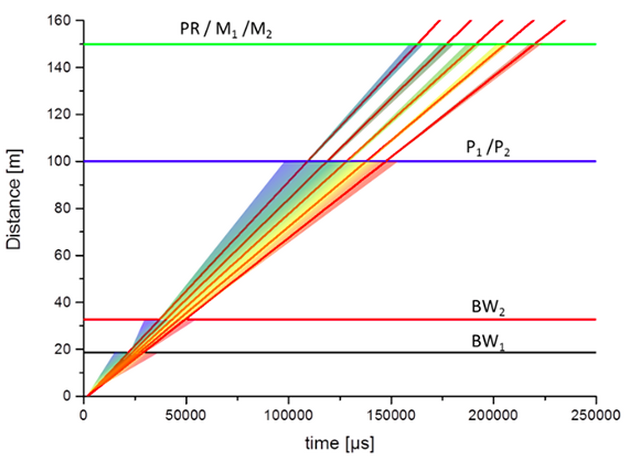

The VESPA chopper system (right inset in Fig. 2) is a central, and probably the most significant, part of the instrument. Used choppers can be classified according to their function into: three pulse shaping choppers (PSC, 3 pairs of counter-rotating discs), one frame overlap chopper (FOC, 1 disc), which can be also understood as a band width chopper (BWC), and one sub-frame overlap chopper (s-FOC, 1 pair of counter-rotating discs). Together (using two PSC’s out of three at the same time) they will form a complex wavelength frame multiplication (WFM) chopper system enabling the planned performances of the spectrometer. The rotation speeds will be indeed very low (154, 28, and 42Hz) if measured against the state-of-the-art capability, but the system will have a peculiarity: the pulse shaping chopper sets, the part closest to the source at a distance ranging from 6.50 to 7.44 m, has to allow the simultaneous use of two chopper pairs leaving the third parked open. For example, the 1st (at 6.50 m) and 2nd (at 6.80 m), while the 3rd (at 7.44 m) stays open (high-resolution mode), or the 1st and the 3rd with the 2nd staying open (low-resolution mode).

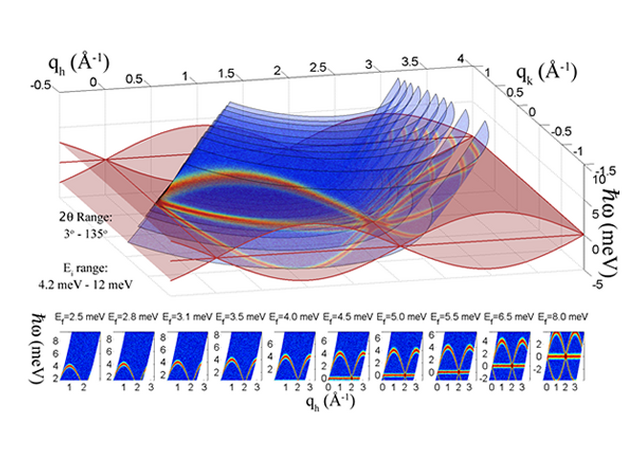

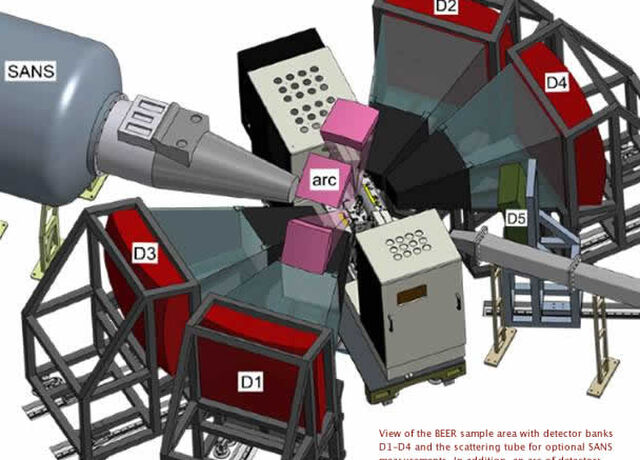

Analysers, Filters and Detectors

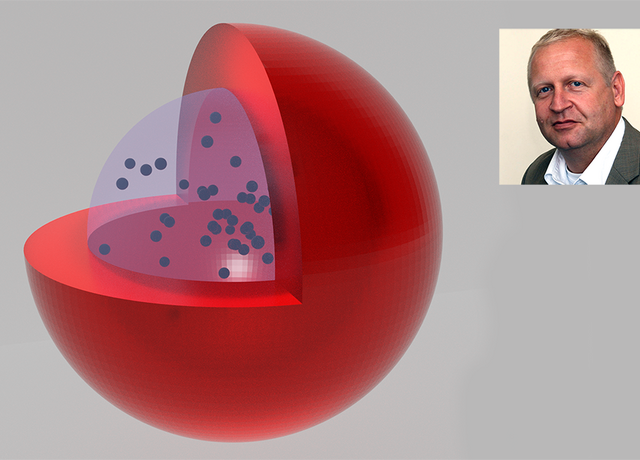

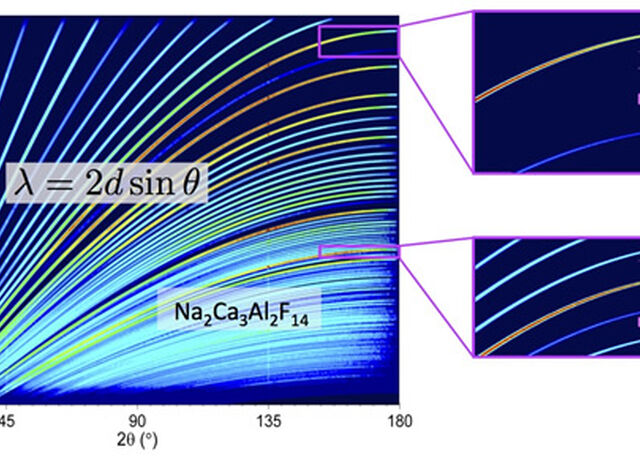

VESPA will use highly oriented pyrolytic graphite (HOPG) crystals (left inset in Fig. 2) to determine the final neutron energy, as fixed by the selected Bragg angle. Such a configuration requires a high-pass filter downstream from the HOPG analyser to remove higher order harmonics before detection. A beryllium filter can be used to fulfil this task. However, this solution works only if the Bragg angle is so large that the first harmonic (l1) exceeds the beryllium threshold at lco=3.966 Å, but so small that the second harmonic (l1/2) does not exceed the same threshold. Thus we have chosen Bragg angles between 40o and 60o, so that the minimum reflected wavelength will be l1(40°)=4.313 Å>lco, while one half of the maximum reflected wavelength will be l1(60°)/2=2.905 Å<lco. The configuration of the spectrometer includes two backscattering analysers sets, placed at scattering angles (not to be confused with Bragg angles!) of 150°(named “external”) and 130°(named “internal”). In this configuration two types HOPG analysers can be distinguished, using Bragg angles of 60°and 40°, respectively. These analysers will select neutrons whose first harmonics are: l1(40°) = 4.313 Å and l1(60°) = 5.811 Å, corresponding to the following final neutron energies: E1(40°) = 4.4 meV and E1(60°) = 2.4 meV, which are fully compatible with the transmission threshold of a beryllium filter (i.e. 5.2 meV). Let us now see some further details:

1) internal analyser set (scattering angle: 130°, Bragg angle: 40°): each HOPG crystal will have a trapezoidal shape with a lower base width of 8 cm, an upper base width of 12 cm and height of 10 cm. The solid angle covered by a single HOPG slab, with respect to the centre of the sample, will be 0.0612 sr. Each slab will illuminate 20 detector tubes (see below for details) through a beryllium filter (cubic, 12 cm edge) forming a module (also known as “analyser-filter-detector module”). Considering 7 modules (one has been removed to leave some space for the sample environment), a total solid angle of 0.428 sr will be provided;

2) external analyser set (scattering angle: 150°, Bragg angle: 60°): assuming the same HOPG crystal shape and 17 tubes, the resulting solid angle, with respect to the centre of the sample, will be 0.0212 sr, providing a total solid angle (8 analyser-filter-detector modules) of 0.170 sr.

Thus the solid angle collected by the whole system of analyzers (backscattering internal and external sets) will amount to about 0.598 sr.

Vibrational spectrometers are normally equipped with standard commercial detectors like, for example, 3He tubes (e.g. 200 mm long). In our case thin cylindrical tubes (e.g. with a 7.9 mm diameter) will be particularly suitable since the reduced value of the neutron travelling path into the tube is highly beneficial to the time-of-flight (i.e. energy transfer) instrumental resolution. However, in this case the gas pressure has to be quite higher (up to 12 bar) than the standard values in order to cope with the detection efficiency. As for the diffraction capabilities, since the requested performances are simply standard, similar cylindrical 3He tubes (but shorter, e.g. 100 mm) will be adequate.

Sample Environment

Publications

Andersen, K. H. et al. The instrument suite of the European Spallation Source. Nuclear Instruments & Methods in Physics Research Section a-Accelerators Spectrometers Detectors and Associated Equipment 957, 39, doi:10.1016/j.nima.2020.163402 (2020).

A. Fedrigo, D. Colognesi, M. Bertelsen, M. Hartl, K. Lefmann, P. P. Deen, M. Strobl, F. Grazzi, and M. Zoppi, The neutron vibrational spectrometer for the European Spallation Source, Rev. Sci. Instrum.87, 065101 (2016).

M. Zoppi, A. Fedrigo, M. Celli, D. Colognesi, VSI@ESS: Case study for a Vibrational Spectroscopy Instrument at the European Spallation Source, Eur. Phys. J. Web of Conf.83, 03021 (2015).

P. C. H. Mitchell, S. F. Parker, and A. J. Ramirez-Cuesta, Vibrational Spectroscopy With Neutrons (World Scientific, Singapore, 2005).

M. Hesse , H. Meier, B. Zeeh, Spectroscopic Methods in Organic Chemistry(Thieme, Stuttgart, 2007).

M. Diem, Introduction to Modern Vibrational Spectroscopy (Wiley-Interscience, Hoboken (NJ), 1993).

Lead Scientists

D. Colognesi, Consiglio Nazionale delle Ricerche

M. Hartl, ESS

Lead Engineer

M. Chowdhury, Science and Technology Facility Council (STFC)

Milano-Bicocca University

L. Di Fresco

G. Gorini

M. Zanetti

F. Masi

A. De Bonis

Science and Technology Facility Council (STFC)

K. Jones

S. F. Parker

Consiglio Nazionale delle Ricerche

C. Vasi

S. Bellissima

L. del Rosso

Università della Calabria

G. Scionti