More than 30 materials science research groups in Aarhus have joined forces to prepare for new neutron and X-ray opportunities at ESS, MAX IV and European XFEL.

- Inauguration of the Centre for Integrated Materials Research (iMAT) at Aarhus University

- Higher flux at ESS means better science and more capacity for neutron research in Europe

- Industry leaders Danish Power Systems and Grundfos see neutrons at cutting edge of R&D

- LINX bridges the gap between science and industry

AARHUS and COPENHAGEN—Across Europe, anticipation is growing for the European Spallation Source (ESS) scientific user program. Still nearly six years away, its impact on the scientific and industrial landscape can already be seen, particularly in Scandinavia, where Sweden and Denmark serve as the facility’s host states.

This movement was underscored most recently in Aarhus, Denmark’s second-largest city, where its more than 30 materials research groups have begun to work together to leverage the world-leading scientific opportunities ESS will provide.

“We see this strategic initiative as a stepping stone to take advantage of the opportunities opening up at advanced international facilities, mainly ESS and MAX IV in Lund, and the XFEL in Hamburg,” says Professor Bo Brummerstedt Iversen, director of the new Centre for Integrated Materials Research (iMAT) at Aarhus University and a former member of the ESS Scientific Advisory Committee.

iMAT was inaugurated on August 15 with a standing-room-only ceremony where the centre’s emphasis was made clear: interdisciplinary materials science research is key to finding the solutions to society’s grand challenges. This echoes strongly the vision of ESS as an organisation and the alignment of goals is no accident.

“ESS is actively working to expand the industrial user base for neutron science as we believe the potential for growth in this area is enormous,” says ESS Director General John Womersley. “As our Danish hosts have long understood, both basic and applied research with neutrons will contribute to the commercial applications that will be necessary to address society’s most important challenges in energy, health care and the environment.”

The Energy Challenge: ESS Will Change the Game

Energy materials, a field in which Professor Brummerstedt Iversen is a leading researcher, will be one of iMAT’s pillars of innovation.

“For the study of several types of energy materials it is essential to be able to see the movement of atoms inside a crystal,” says Brummerstedt Iversen. “Neutron beams are the best source for this purpose. One example is lithium batteries. The limited number of electrons in lithium batteries makes X-rays less attractive compared to neutron scattering.”

Professor Brummerstedt Iversen and his group have undertaken many neutron-based studies, but have been held back by the available beam time at existing facilities as well as the limited neutron brightness of those facilities.

“Obviously, the new capacity that ESS will bring is good news, and it is even at a convenient distance from ourselves. But the real game changer will be the possibility to do experiments that are currently out of reach. This is especially true for in operando studies. In ESS we will be able to see the processes taking place in a battery, a thermo-electric module, or a fuel cell during normal operation.”

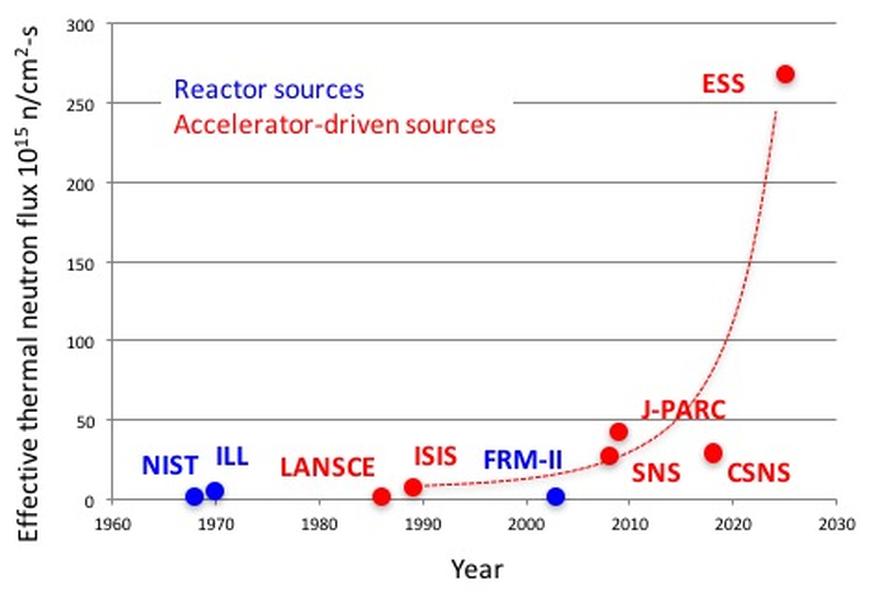

A further advantage is the sheer power of ESS compared to other facilities. One critical parameter in neutron research is termed the “flux”, which denotes the number of neutrons travelling through a given unit area during a given period of time. Neutrons are difficult to generate and require large nuclear reactors or spallation sources to produce in abundance. They are also neutral particles, and unlike X-rays and other techniques based on charged particles the neutrons cannot be easily steered to obtain higher concentrations at certain desired points.

Low flux, then, is often the limiting factor in neutron investigations. The spallation process at ESS, however, will generate enough neutrons to increase the flux by as much as a factor of 100 for certain techniques. This translates into a dramatic increase in capacity while also opening doors to new types of investigations. One can moderate the beam to optimize certain parameters like resolution, or choose to do the same experiments as before, but at a much higher speed.

The opportunity to do in operando studies is maybe even more relevant for industry, Brummersted Iversen points out:

“Often, companies will be able to probe their actual, commercial products directly, and this can even be without moderations. For instance, we can keep the casing around a battery on, as the neutron beams will just penetrate. This is not possible with X-rays.”

Danish Power Systems: Keen on Neutrons

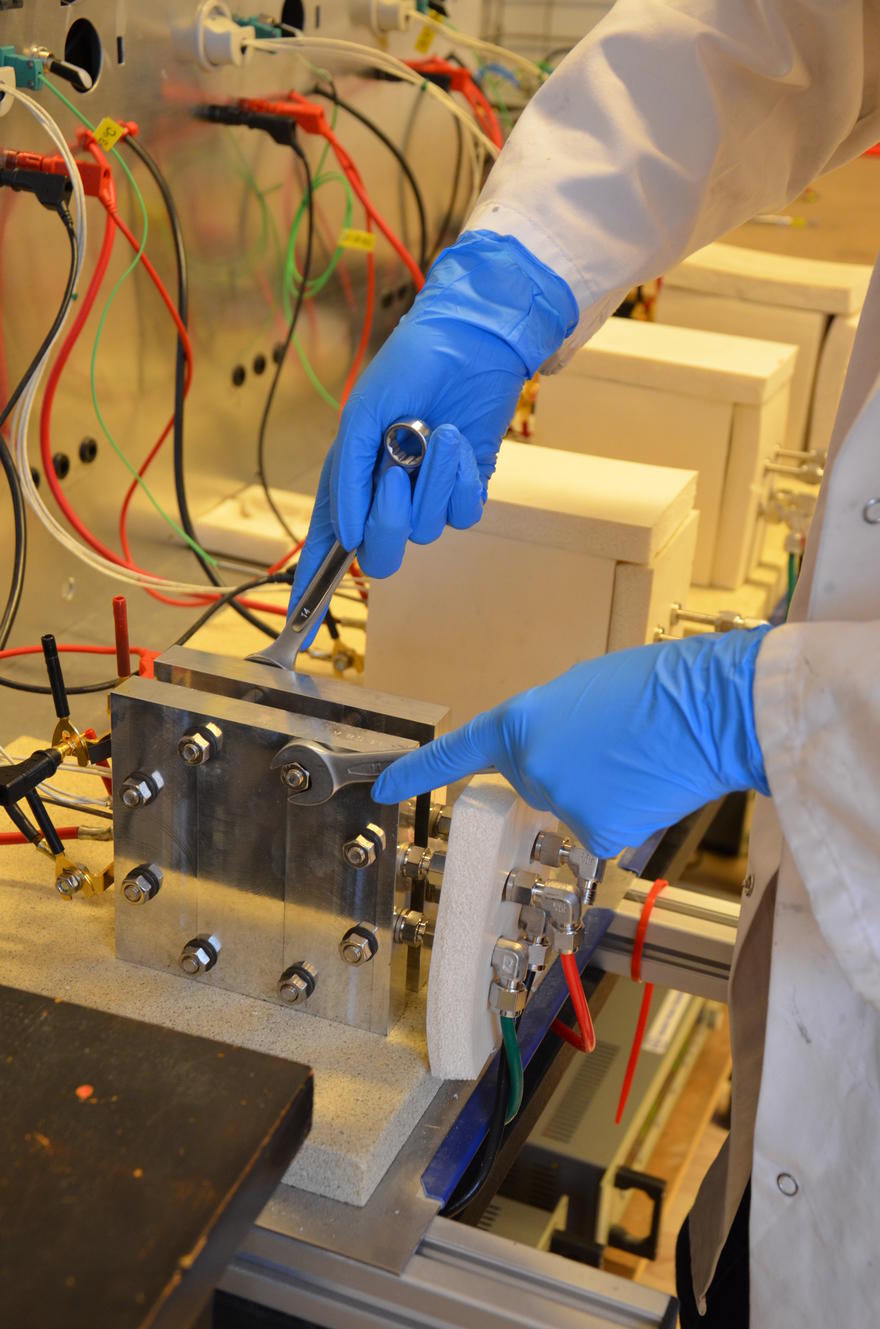

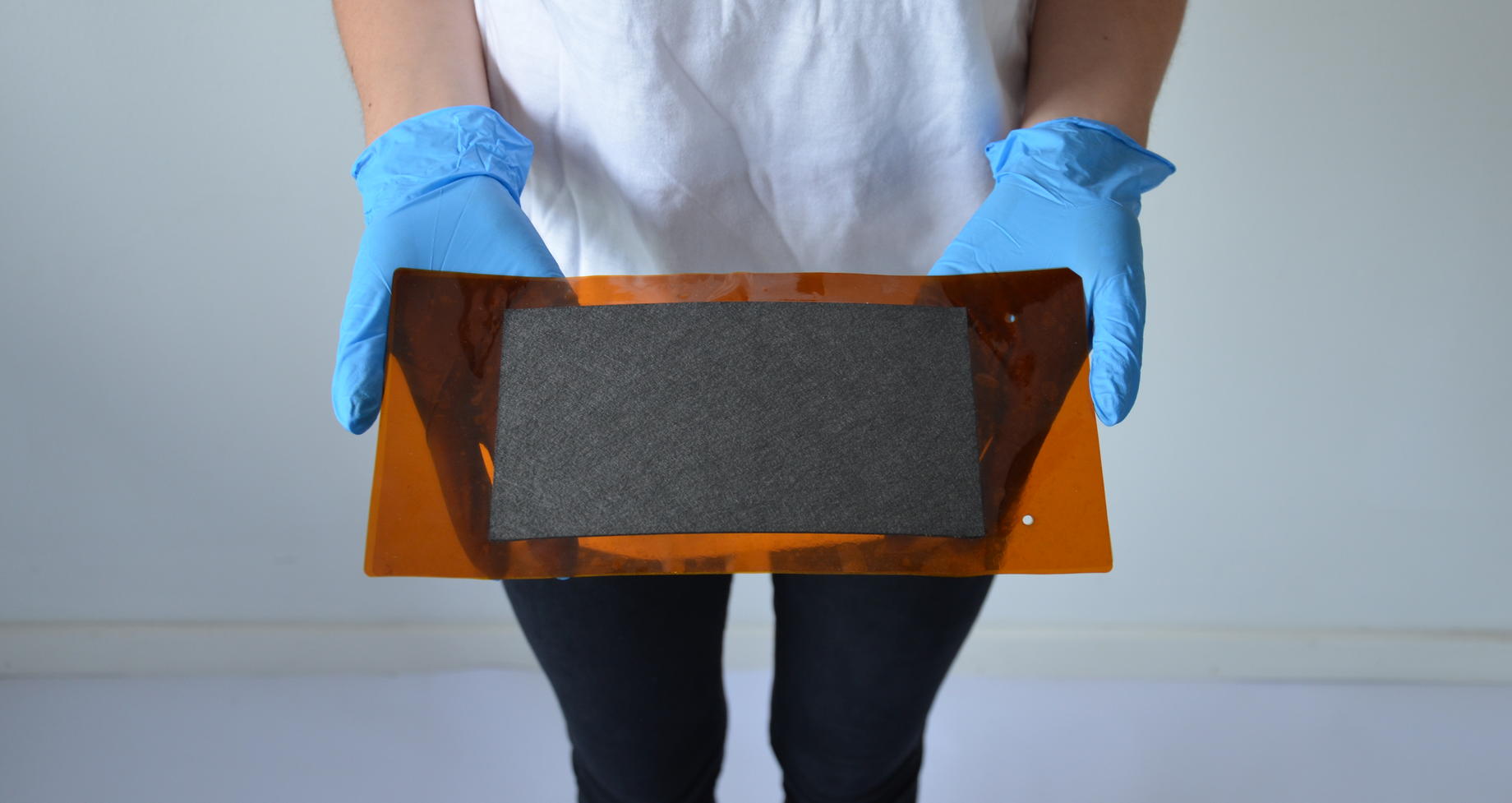

Danish Power Systems (DPS) specializes in fuel cells of the Polymer Electrolyte Membrane (PEM) type (pictured above). Fuel cells transform either pure hydrogen or a hydrogen-rich energy source into electric power with high efficiency and extremely low environmental impact.

DPS manufactures the single PEM cells, which are the starting point for fuel cell systems. A major market is Uninterrupted Power Supply (UPS) systems, for instance for telecommunication towers in areas with unreliable power supply. Given the environmental advantages, a wider use of fuel cells would be desirable. However, the price remains a limiting factor for new applications.

“Much like in a battery, you have a range of chemical reactions taking place in a fuel cell during operation,” explains DPS CEO Hans Aage Hjuler. “Precise knowledge of these reactions, and how they are affected by the physical structure of the cell, and the catalysts applied, will allow us to control manufacturing better. Ultimately, this will allow us to make fuel cells that are both more efficient and cheaper.”

Neutron science instruments are essential to advancing these investigations.

“We know positively that foreign universities and research organizations working on cells similar to ours have done in operando neutron beam experiments,” says Aage Hjuler. “We are keen to have experiments done, once ESS opens. In general, I am confident that industry will get on board research at ESS through joint projects with university groups.

“Personally, I strongly advocate funding for academic research, including fundamental research. As for applied research, I like the present systems under the Danish innovation fund [Innovation Fund Denmark] by which companies need to provide co-funding. This secures that industry has a genuine interest in a given project. The Danish involvement in ESS is a grand contribution. My hope is that this will be followed up with programs that allow a company like ours to take part in projects!”

Grundfos: Bridging from Materials to Integration

More than 16 million units sold annually make Grundfos one of the world’s leading suppliers of pumps. The company is a member of the Danish LINX Association, “a platform for linking industry to neutrons and X-rays” that is sponsored by Innovation Fund Denmark.

“Only rarely will we be at the cutting edge of materials research in a traditional understanding,” explains Allan Holm, Lead Materials Specialist at Grundfos. “However, we strive for absolute excellence when it comes to application of materials in our context. To achieve that we do need a deep understanding of the materials, but even more importantly we need to understand what happens at the interfaces between the different types of components and materials.”

Many Grundfos products are required to survive challenging environments for instance in water management, waste water and sewage systems.

“These challenges make it imperative for us to understand how any changes we consider in our products or manufacturing processes will influence the aging of components, and ultimately the expected lifetime. An interesting feature for the new large-scale facilities such as ESS is the possibility of studying entire systems, not just samples. This promises to bridge the traditional materials research with the integration perspective, which is so important to us.”

Closing the Gap: Academic Guidance for Industry Users

Through LINX, Grundfos and other companies are cooperating with groups at Aarhus University, the University of Copenhagen and the Technical University of Denmark (DTU).

“Experiments at an advanced facility like ESS require a high level of neutron beam expertise,” says DPS’s Holm. “It is only natural that we take advantage of the know-how of academic groups with extensive experience in the field. Right now, we see our main contribution as providing challenges from real life. For the foreseeable future, we will depend on cooperation with academic groups. We will need some guidance on which problems can benefit from advanced studies, and on how to plan and execute these experiments. Also, the university researchers can assist in interpreting results.”

Along the same line, Brummerstedt Iversen does not expect industry projects to dominate the use of ESS from day one:

“Most industry users will probably be introduced to the field through cooperation with university groups. It is very much an ambition of iMAT to encourage such cooperation, just as we will continue to be very active in LINX in cooperation with DTU and the University of Copenhagen. It is still early days for most companies to consider neutron-based techniques. But then again, not so many years ago it was quite exotic for industry to consider X-ray-based techniques. Today, this is an integrated part of materials development in a range of companies, and I am certain that we will see a similar development for neutron-based techniques.”