BEER

Engineering Diffractometer

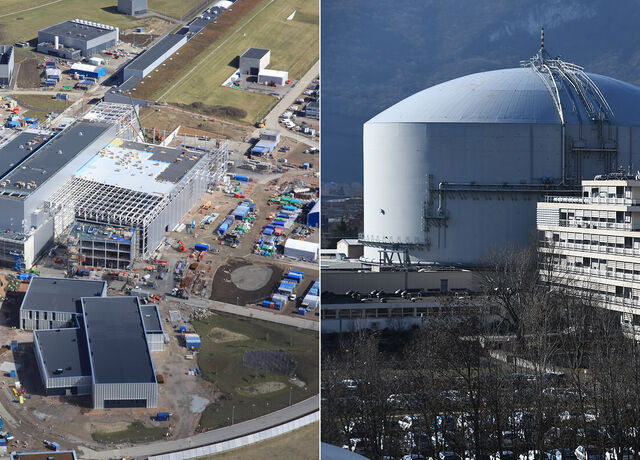

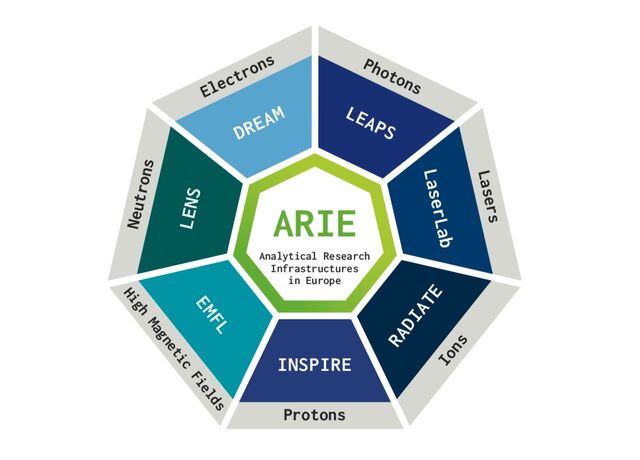

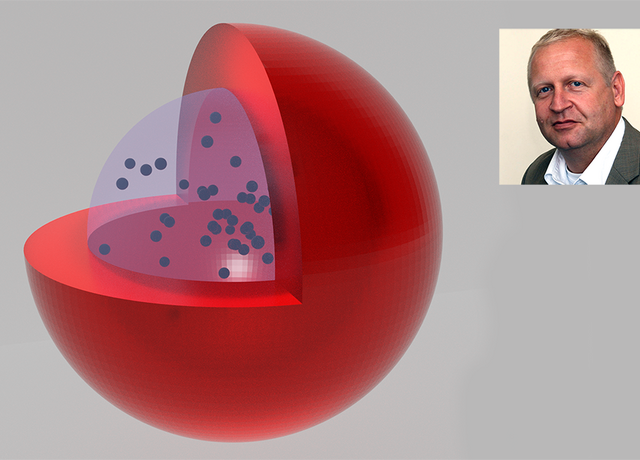

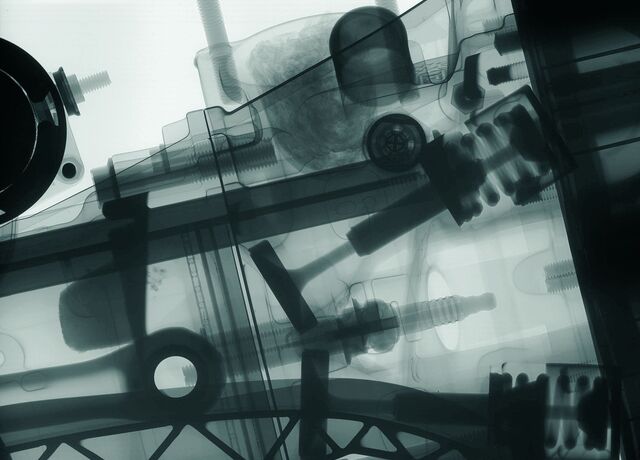

The time-of-flight materials engineering diffractometer BEER built by the partners Helmholtz-Zentrum Hereon from Germany and the Nuclear Physics Institute, CAS (NPI) from the Czech Republic offers new opportunities for investigation of deformation mechanisms, microstructure evolution and phase transformations in materials developed for high-tech industrial applications in situ under real processing or operating conditions. The high ESS flux combined with the novel beam modulation technique will allow non-destructive mapping of residual strains in construction components with unprecedented speed.

Instrument Class

Beam Port

Lead Scientist

Lead Engineer

The continuous development of advanced structural materials and novel manufacturing processes are key for European manufacturing industry to stay competitive and ensure clean transport and clean energy generation. This includes the development of sustainable material and processing solutions protecting natural resources.

For instance, in order to stay competitive, automotive, railway, and aerospace industries require continued development and intelligent use of high-performance materials with the aim of increasing operation safety while reducing fuel consumption and emissions. Structural materials are multiphase and multiscale; they are exposed to extremely complex processing procedures and often operate in highly demanding environments.

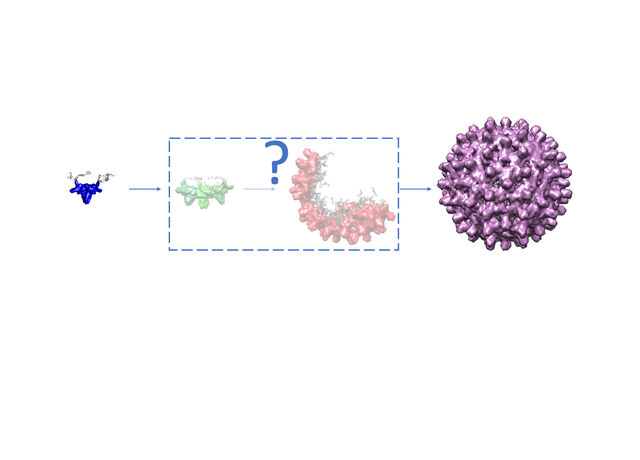

Future successful research efforts will require a cradle-to-grave approach, i.e. understanding micro/nanostructure and residual stress evolution during processing and their role in the mechanisms that determine material and component performance. To date, progress has been based on empirical understanding, and component lifing assessments are effectively curve-fitting exercises demanding large safety margins. It is becoming increasingly clear that further progress, and hence keeping a competitive edge, can only be achieved by replacing empirical data with physical and mechanistic understanding. This will ensure the development of both novel and improved uses of existing materials, by employing physically informed analyses on the process and lifing models. BEER will be instrumental in this development, as it will move analytical processing and performance research from post-mortem analysis to yet unparalleled in situ or in operando analysis.

Neutron diffraction is already a well-established tool for characterization of engineering materials and components (internal stresses, textures, deformation processes). Moreover, there is a growing materials engineering community using neutron facilities worldwide, which correlates with the development of new engineering beamlines.

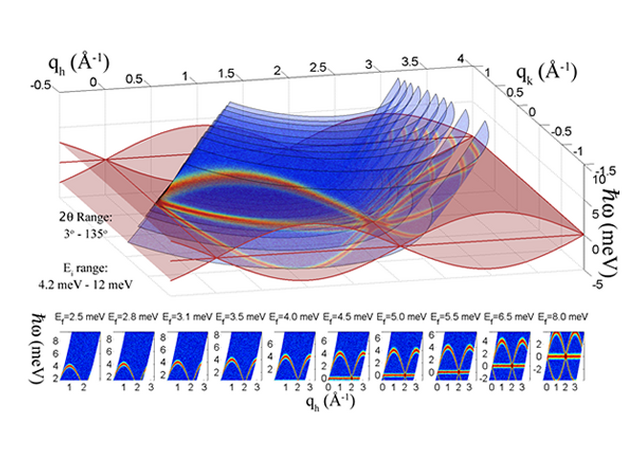

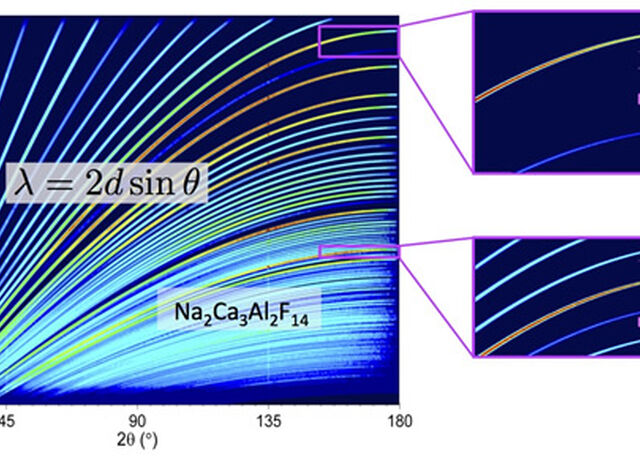

The main purpose of the BEER diffractometer is, on the one hand, to enable time-resolved in situ and in operando investigations of structural materials during processing and exposure to simulated service environments. On the other hand, the instrument offers the possibilities for state-of-the-art technologies for efficient and precise characterization of residual stresses, crystallographic textures and phase compositions in structural materials.

The concept of BEER for ESS is based on a vast improvement in data acquisition times compared to current materials engineering flagship instruments, flexible detector cover and complex environments. It consists mainly in:

- adopting state-of-the-art technologies for efficient and precise residual stress and microstructure/crystallographic texture characterization of structural materials and

- developing new strategies for time-resolved in situ/in operando investigations of structural materials during processing and exposure to simulated service environments that become possible with the high intensity at ESS.

Thus, new opportunities will be offered to material engineers for following micro- and nanostructures, textures, and internal stresses evolving at industrially relevant temperatures, strain rates, and complex loading conditions to investigate and develop thermomechanical processing procedures as well as deformation mechanisms during service conditions.

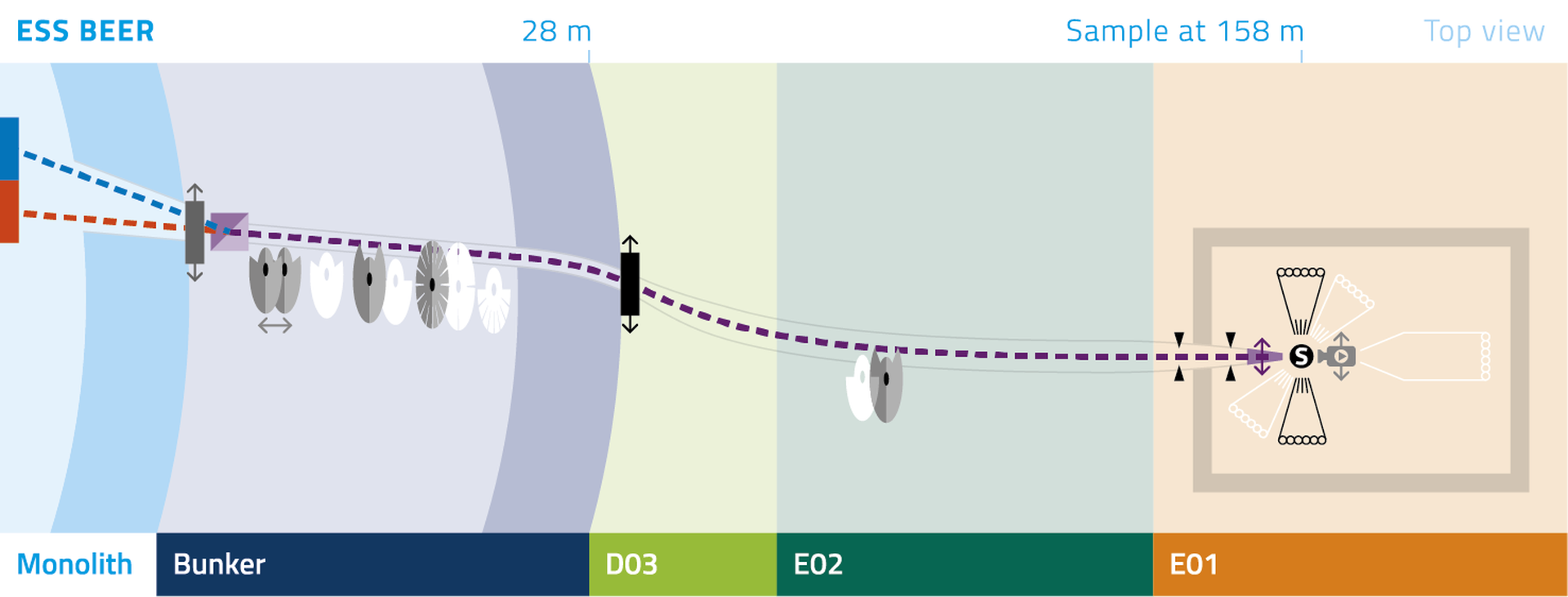

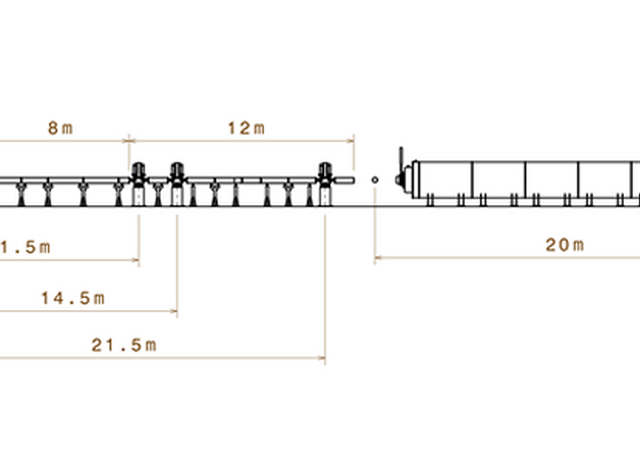

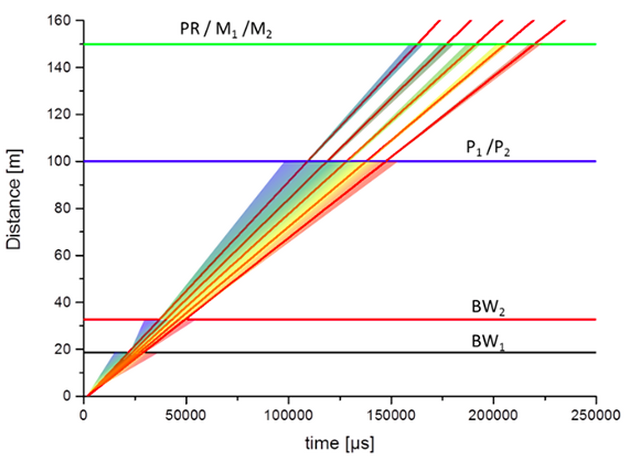

The instrument BEER will be a 158 m long time-of-flight diffractometer. The basic instrument layout consists of a bi-spectral extraction system after the target monolith which enables the usage of neutrons from the thermal and cold range in the instrument.

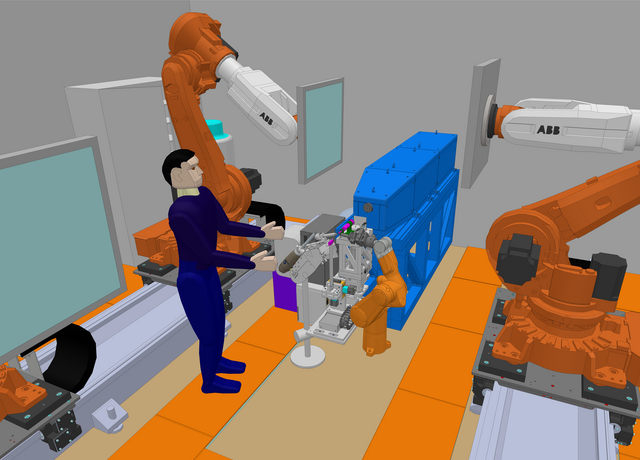

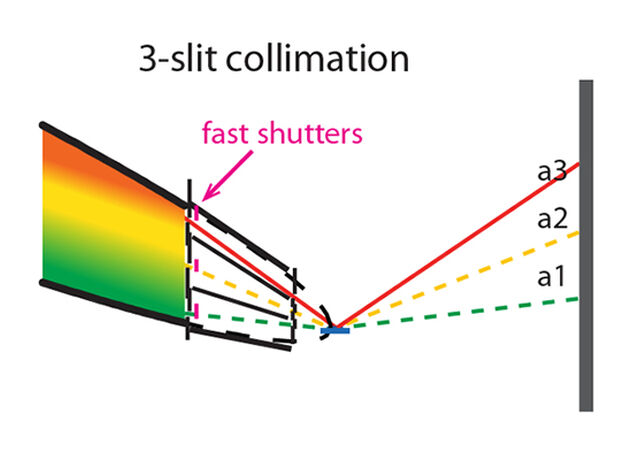

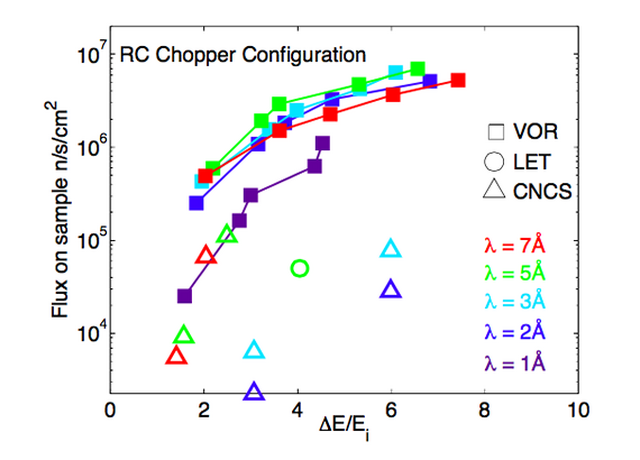

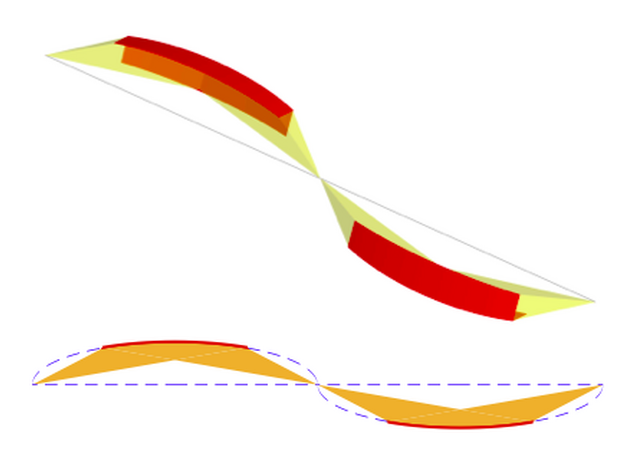

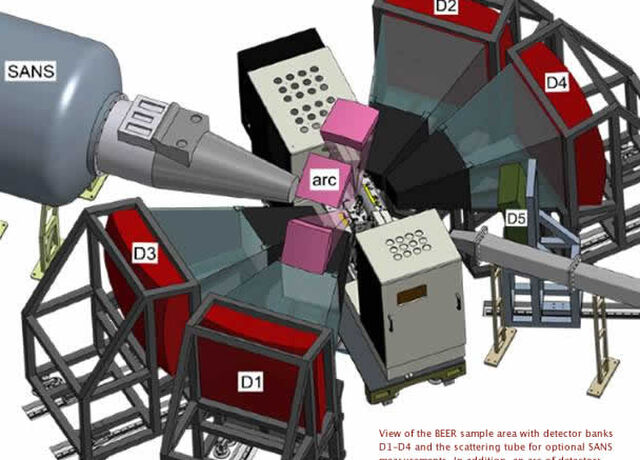

The choppers within the common bunker allow for the pulse shaping method in the optical blind mode and the new pulse modulation technique. In the latter case, not only one short pulse is extracted from the long ESS pulse but several, leading to a substantial intensity gain of up to an order of magnitude compared to pulse-shaping methods for materials with high crystal symmetry. Additional choppers within the bunker and at about 80 m from the source are used for wavelength frame definition. The neutron transport system consists of straight guide elements in the chopper section followed by expanding and curved guide segments blocking the direct line of sight twice, thus allowing a good signal-to-noise ratio. Divergence slits and an exchangeable focusing guide at the end of the transport guide allow tuning the resolution and intensity to the needs of the experiments. The sample stage surrounded by 2 detectors at ±90° in a distance of 2 m to the sample offer sufficient space for bulky samples and sample environments.

Sample Environment

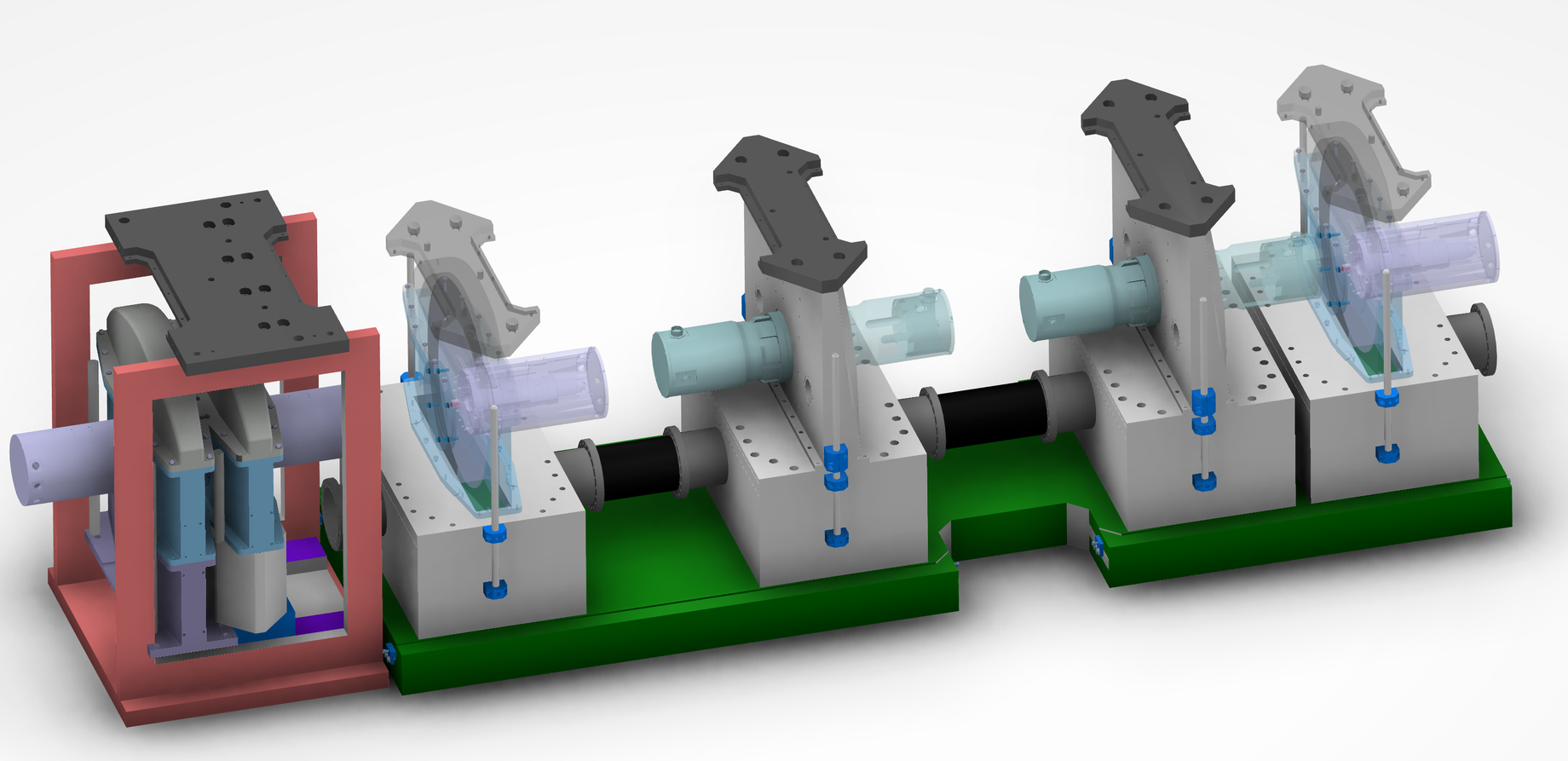

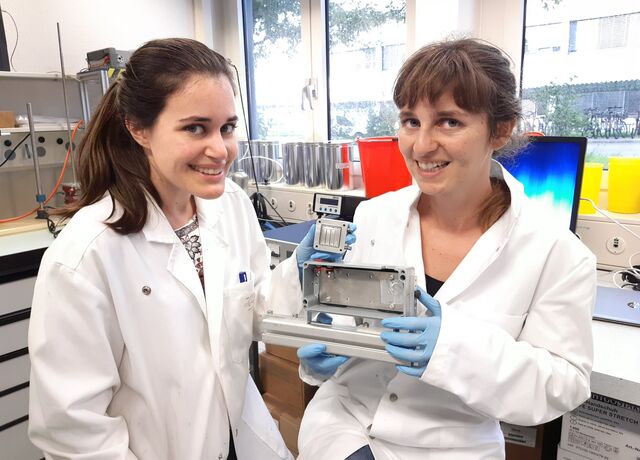

The day-one sample environment includes a heavy load hexapod with a payload up to 2 t and a six-axis robot with a payload up to 14 kg allowing for automatic sample change and measurements.

Together with a stress rig with a max. load of 60 kN quipped with a furnace for temperatures up to 1200°C which allows the in situ treatment of the sampls. Additionally, a dilatometer offers the capability for fast heating (4000K/s) and cooling (2500 K/s) of the sample during compression or tension with a load of max. 25 kN.

- Andersen, K. H. et al. The instrument suite of the European Spallation Source. Nuclear Instruments & Methods in Physics Research Section a-Accelerators Spectrometers Detectors and Associated Equipment 957, 39, doi:10.1016/j.nima.2020.163402 (2020).

- M. Rouijaa, R. Kampmann, J. Šaroun, J. Fenske, P. Beran, M. Müller, P. Lukáš, A. Schreyer, Beam modulation: A novel ToF-technique for high resolution diffraction at the Beamline for European Materials Engineering Research (BEER), Nuclear Instruments and Methods in Physics Research, Section A: Accelerators, Spectrometers, Detectors and Associated Equipment. 889 (2018) 7–15. doi.org/10.1016/j.nima.2017.12.083.

- J. Fenske, M. Rouijaa, J. Šaroun, R. Kampmann, P. Staron, G. Nowak, J. Pilch, P. Beran, P. Šittner, P. Strunz, H.-G. Brokmeier, V. Ryukhtin, L. Kadeřávek, M. Strobl, M. Müller, P. Lukáš, A. Schreyer, BEER-The Beamline for European Materials Engineering Research at the ESS, J. Phys.: Conf. Ser. 746 (2016) 012009

- J. Šaroun, J. Fenske, M. Rouijaa, P. Beran, J. Navrátil, P. Lukáš, A. Schreyer, M. Strobl, Neutron optics concept for the materials engineering diffractometer at the ESS, J. Phys.: Conf. Ser. 746 (2016) 012011

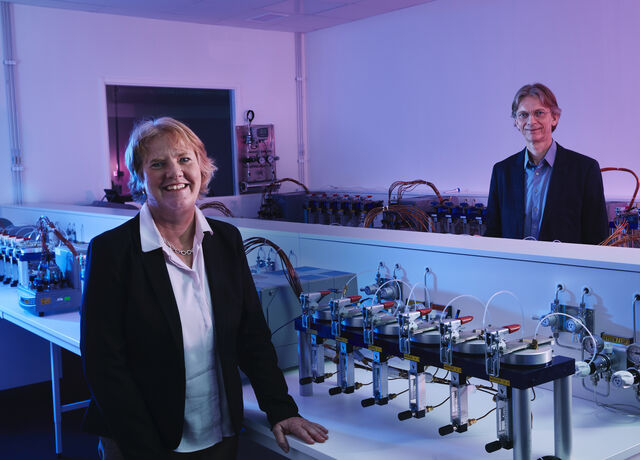

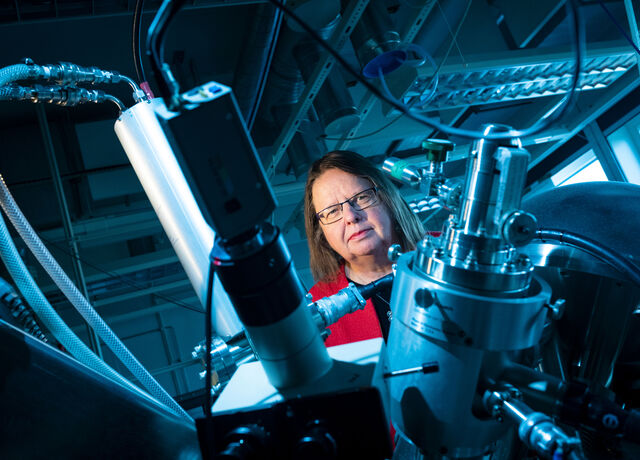

Lead Scientists

Premek Beran - Nuclear Physics Institute, CAS, Czech Republic

Gregor Nowak – Helmholtz Zentrum Hereon, Germany

Lead Engineers

Bojan Peric - ESS

Dirk Jan Siemers - Helmholtz Zentrum Hereon, Germany

Engineers

Jörg Burmester - Helmholtz Zentrum Hereon, Germany

Project Coordinators

Jochen Fenske, Helmholtz Zentrum Hereon, Germany

Jan Saroun - Nuclear Physics Institute, CAS, Czech Republic