Site, Architecture & Sustainability

The European Spallation Source will be one of the most advanced science infrastructure projects ever built. The architecture and design of ESS should reflect and contribute to the organisation’s core values: excellence, collaboration, openness and sustainability.

Site

The ESS site is located in a highly developed scientific and industrial environment, providing access to an educated and technically-skilled workforce, and with proximity to Lund University and other major research centres.

The ESS facility is being built on a site totalling approximately 70 hectares located on the northeast outskirts of the Brunnshög district of the city of Lund, in close proximity to the MAX IV synchrotron facility.

Both ESS's and MAX IV's construction plans call for an area between the two facilities, a “Science Village”, which will include shared infrastructure and services. The Brunnshög district is currently undergoing extensive growth and development. A mixed-use neighbourhood is being planned, with around 3,000 dwellings and businesses providing employment for 20-25,000 individuals by 2025.

Previous archaeological excavations made in the farmland north of Lund, where the ESS construction site is located, detected early settlements indicating that the area has been populated for millennia.

An extensive programme of archaeological investigations was carried out by a team of archaeologists managed by the Swedish National Heritage Board (Riksantikvarieämbetet) before construction began.

Antiquity Meets the Future—Archaeology at the ESS Site was published in 2015 to accompany an exhibit of the findings at the Lund Historical Museum.

Further reading:

- Facebook: Arkeologi på ESS

- Blog at Swedish National Heritage Board web site

- Three-volume final report at Samla-Riksantikvarieämbetets (in Swedish)

- ANDERSSON, Magnus; ARTURSSON, Magnus; BRINK, Kristian. Early Neolithic Landscape and Society in Southwest Scania – New Results and Perspectives. Journal of Neolithic Archaeology, [S.l.], p. 23–114, july 2016. ISSN 2197-649X. doi: https://doi.org/10.12766/jna.v18i0.118

- Schulz Paulsson, B., Andersson, M., Artursson, M., & Brink, K. (2017). A Highly Precise Chronology for the Process of Neolithization in Southern Scandinavia: The ESS Project in Lund, Sweden. Radiocarbon, 59(2), 583-593. doi:10.1017/RDC.2016.72

Landscaping and urban planning of the ESS site requires the same level of careful attention as the design of buildings.

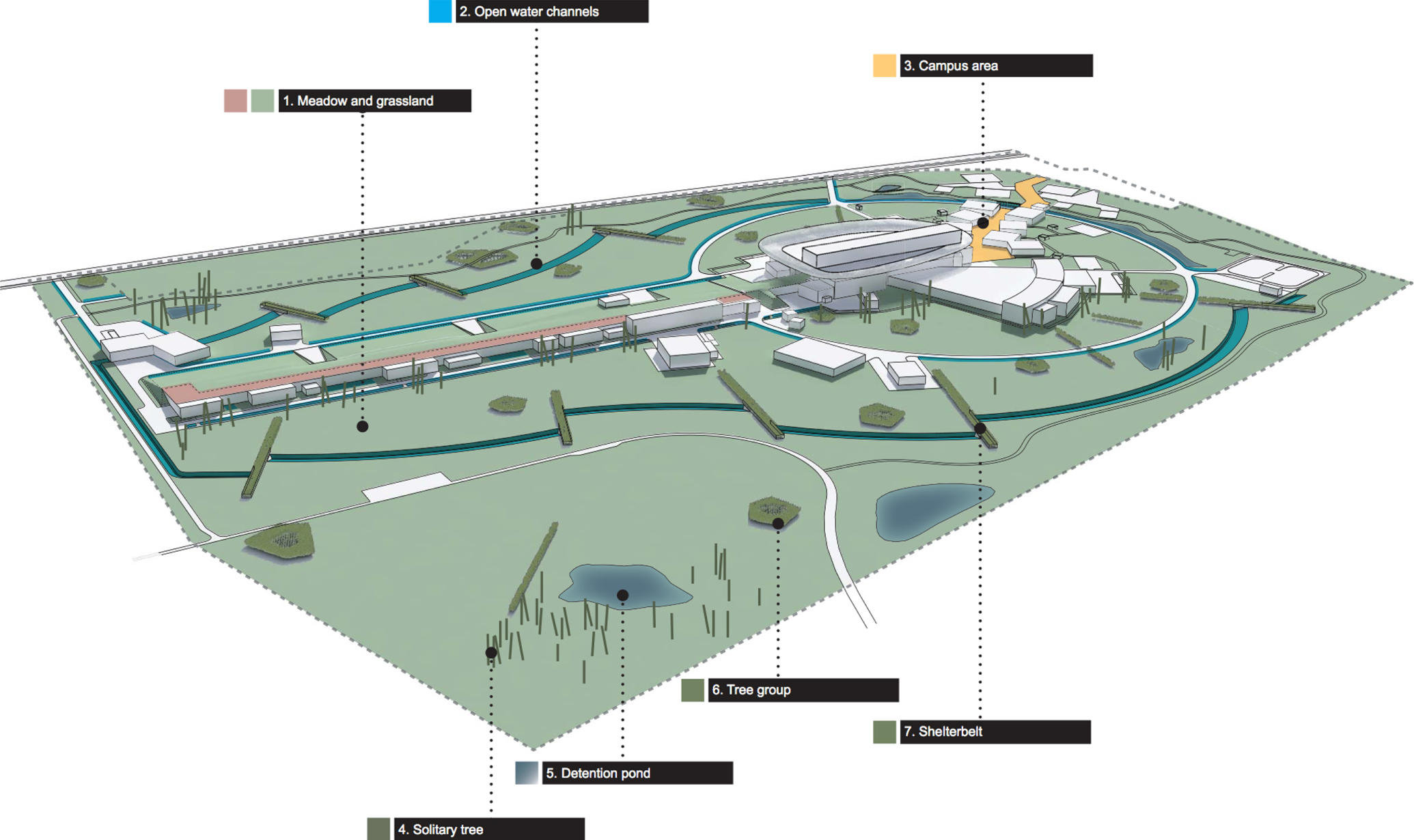

As the facility stretches out over almost 1 km2 of land and the chosen site is on a ridge rising above the surrounding landscape, ESS will direct particular attention to the layout of the site, flexible development, and transportation within the site, while considering views of the site from neighbouring locations. The challenges and unpredictability of the Scandinavian climate during winter will be taken into account, and the effects minimised, when planning the landscape design. ESS will promote biodiversity in the area as the site neighbours parkland and the typical rural landscape of the Scania region of southern Sweden.

Terracing for the accelerator, target, and instruments will be carried out to accomplish a common ground level, balancing the masses within the designated area, which minimises the need for transport of soil. Use of storm water ponds and open ditches will create a pleasant and natural outdoor environment. Trees, bushes, and other landscaping elements will contribute to the goal of a soft and green environment around the facility, and connect it with the surrounding farmland.

A system of roads and pathways is planned around the buildings to facilitate transport and access for various types of traffic across the site, including heavy transportation, bicycles, and pedestrians.

Sustainability is an important factor when planning the road structure, therefore pedestrians and cyclists will be given priority over car traffic.

When planning the parking requirements for the facility, the fact that ESS will be frequently visited by many guest researchers has been taken into consideration. Landings sufficient for loading and unloading heavy goods at the loading bays are required. Bicycle parking facilities are located near entrances, and a bicycle 'tent' with good lighting and weather protection is situated near the temporary ESS reception area.

As part of the ESS “zero impact vision”, where the goal is to avoid emitting any pollutants into the environment, a system for treating polluted storm water is designed.

The goal will be to clean the water in such a way that the storm water running back to the natural streams will not deteriorate the environmental status of the stream or its surroundings. To avoid an overload of existing drainage systems, the storm water flow from the development site will be collected, through pipes and open systems, in detention ponds with regulated outlets. There will be a closing device on the detention ponds in order to facilitate sample-taking, treatment, and disposal of polluted storm water.

Architecture

Many of the buildings at ESS will be technical utility buildings of an industrial nature, which imposes limits and challenges for the architectural design. The architectural conceptualisation of the buildings is vital for the visual impact of the facility and for the integration into the surrounding landscape and neighbouring Science Village.

After an international design contest held in 2012, and a following negotiated procedure, Team Henning Larsen Architects was chosen to develop the overall architectural concept. The contest jury’s motivation was the following:

The proposal shows great skill and sensitivity in creating in-between spaces and a strong urban context. There is a strength in the campus concept and the possibility to achieve differentiation and variation in buildings and places. The link to Science Village is a clearly expressed theme well developed in the proposal. There is a human scale represented as well as a dramatic scale in the roof structure.

The architectural strategy is based on three layers of design:

The central element of the spallation process, the tungsten target wheel, is used as inspiration for the roof of the Target Station and Experimental Halls, in order to create one coherent image of ESS.

Sustainability

The European Spallation Source (ESS) will be one of the world’s first sustainable research facilities. One of the major challenges to accomplish this will be the facility’s energy consumption and costs related to it. ESS's energy concept is the primary tool for realising this goal. Other sustainability actions include BREEAM certification of the permanent offices, biodiversity and the sustainable selection of materials

ESS is a long-term commitment that will benefit coming generations and contribute to managing global environmental challenges both by scientific results and by how the facility itself is built and operated.

Setting a new standard for how research infrastructures are managed over their life cycle is an important development for the future.

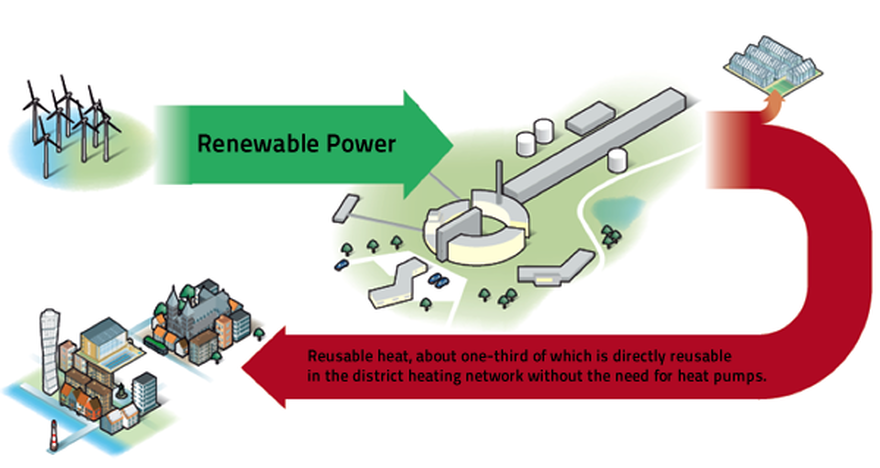

ESS is committed to an energy concept that consists of three parts: Responsible, Renewable, Recyclable.

The main aim of the Responsible concept is to monitor the estimated electricity consumption of ESS so it stays below the committed 270 GWh and to predict future energy-related operations costs with the possibility to lower these as much as possible for the benefit of science.

Systematic energy management involves creating and maintaining an inventory of energy flows, including temperature levels. Together with system audits, this will be the base for an Energy Management System consisting of an energy guideline, follow-up and reporting.

The cyclic energy inventory encourages and maintains continuous dialogue between the Environment, Safety & Health Group and all the other projects, thereby promoting a strong energy culture at ESS.

The maximum amount of electricity required for the operation of ESS has been estimated to be around 270 GWh/year, which is approximately the same as the annual consumption of 40 000 apartments or of a small Swedish municipality. When ESS is fully commissioned, the power consumption in Lund will rise by 20-30%.

When it comes to the supply of electricity to the facility, ESS has two main policies:

-

ESS is committed to renewable power production in order to compensate for the increased power consumption caused by ESS

-

It is vital for research operations that the cost of electricity for running the facility is competitive, stable and predictable

The first and second policies together imply that ESS cannot just buy electricity from an existing power source or directly from the 'spot-market'. The Renewable promise, combined with low cost, stability and predictability, makes it necessary for ESS, at least initially, to enter into a partnership with other consumers to increase the total electricity consumption volume in order to have influence on an agreement with a Balance Responsible Party (BPR). This BPR will handle the electricity consumption of the partners as a common portfolio.

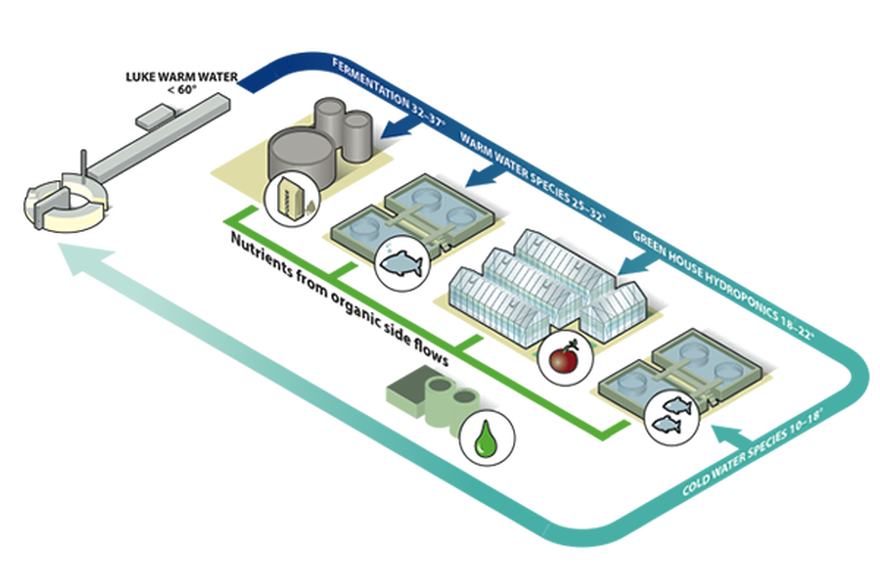

ESS is committed to not only the Recycling of surplus energy from its operations but to also achieve this in a responsible manner. The total amount of surplus energy is estimated to 254 GWh annually, and consists of hot water that is a result of the cooling process in the facility.

In order to optimise heat recovery efficiency, the cooling system is calculated to operate at three temperature levels, where the high-temperature waste heat can be transferred and recycled directly into a district heating network. The lower temperatures are suitable for heating ESS’s own buildings, and possibly even other buildings in the area of Brunnshög through low temperature district heating.

ESS is committed to certify the office buildings at Campus according to the internationally recognised environmental assessment method for buildings, BREEAM. The BREEAM system gives the freedom to choose among different possible credits in order to arrive at a final rating. The credits are distributed among nine different areas:

-

Management

-

Health and Well-being

-

Energy

-

Transport

-

Water

-

Materials

-

Waste

-

Land Use and Ecology

-

Pollution

The targeted overall final score for the buildings is Outstanding, which is the highest possible score.

Construction of the office is ongoing and should be ready for move-in Q1 2021. Reconciliation of BREEAM will take place in part after completion of the planning stage (Q1 2020) and in part after the end of construction (Q1 2021).

An ecological inventory has been carried out at the ESS property as part of the BREEAM work. The inventory showed that the ESS site prior to construction was dominated by a monocultural planting strategy, which, from a preservation perspective, has no real value. There are certainly smaller areas on the site which could be suitable for preservation; the marl pit, the transition areas between fields and roads, and a pond. However, the area in general does not contain plantings, habitats or ecological systems which cannot be restored or are of high value from an ecological point of view.

During the time ESS borrows the excellent-quality farmland for research purposes, the ecosystem services of the property are changed from food supply to ecosystem support. The productive monoculture is exchanged for increased biodiversity. In order to improve the ecological value of the site, the topography will be changed into a more varying terrain and native vegetation will be implemented, with the landscape concept shown above. The terrain, ponds and vegetation create a broad variation of habitats with different microclimates, hiding places, water and food supply, green corridors and nesting sites. Flowering and fruiting species are chosen to enhance pollinating insects, bees and birds, while shallow ponds improve the living conditions for amphibians. The rich fauna also contributes to a recreational environment for visitors, locals and employees at ESS.

As part of its sustainability commitment, ESS has developed a procedure for the sustainable selection of materials. The aim is to minimise the environmental impact from products through a life cycle approach. The procedure states four main requirement areas:

-

Content of hazardous substances -

Life cycle impacts -

Responsible sourcing -

Documentation of product data

The requirements apply to certain products and materials that are to be built into the facility. As ESS collaborates regularly with partners in the Swedish construction industry, these types of requirements are well-known, and the large Swedish contractors have procedures in place to be able to handle such requirements efficiently.