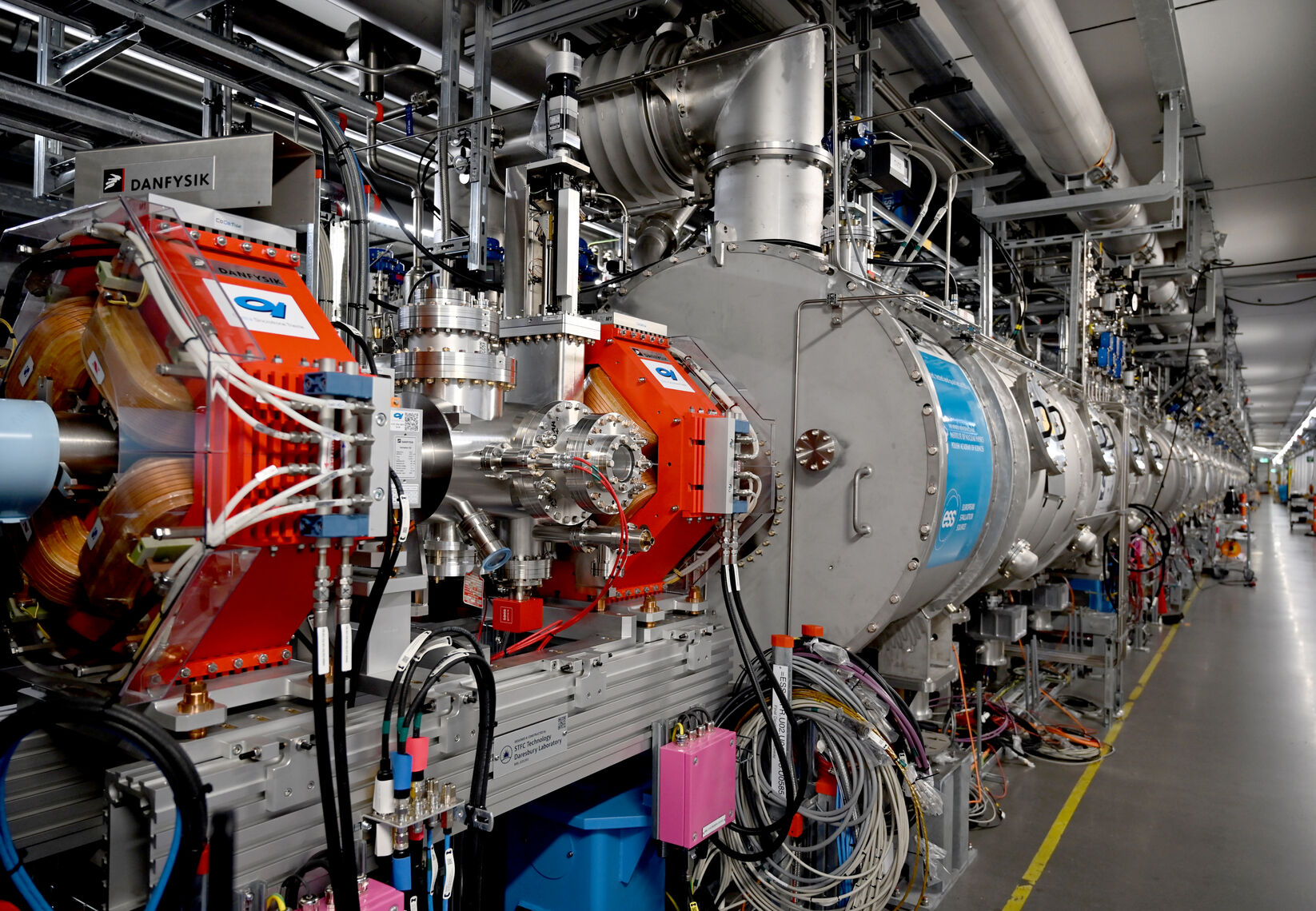

ESS is steadily progressing towards the completion of installations in the accelerator, with the goal of sending the first proton beam to the tuning beam dump by early 2025.

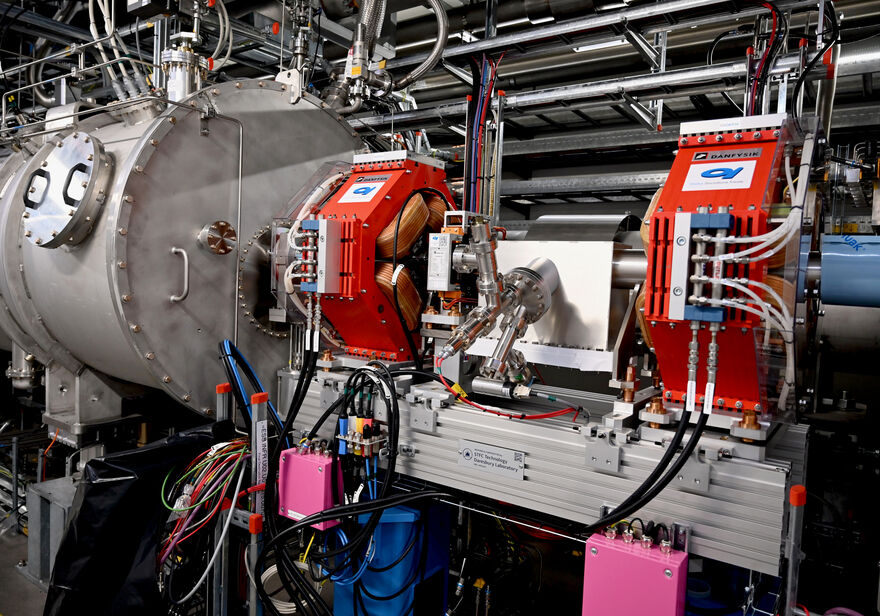

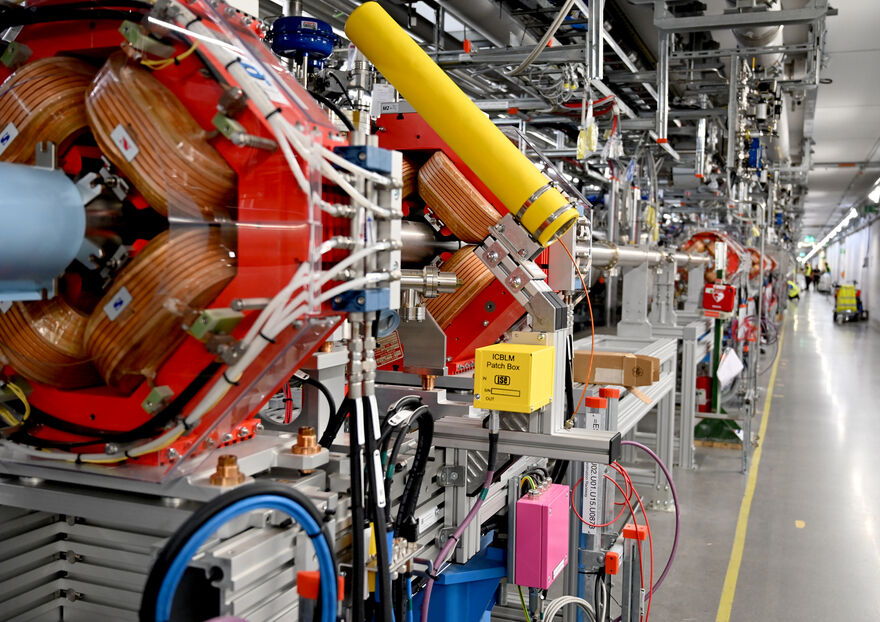

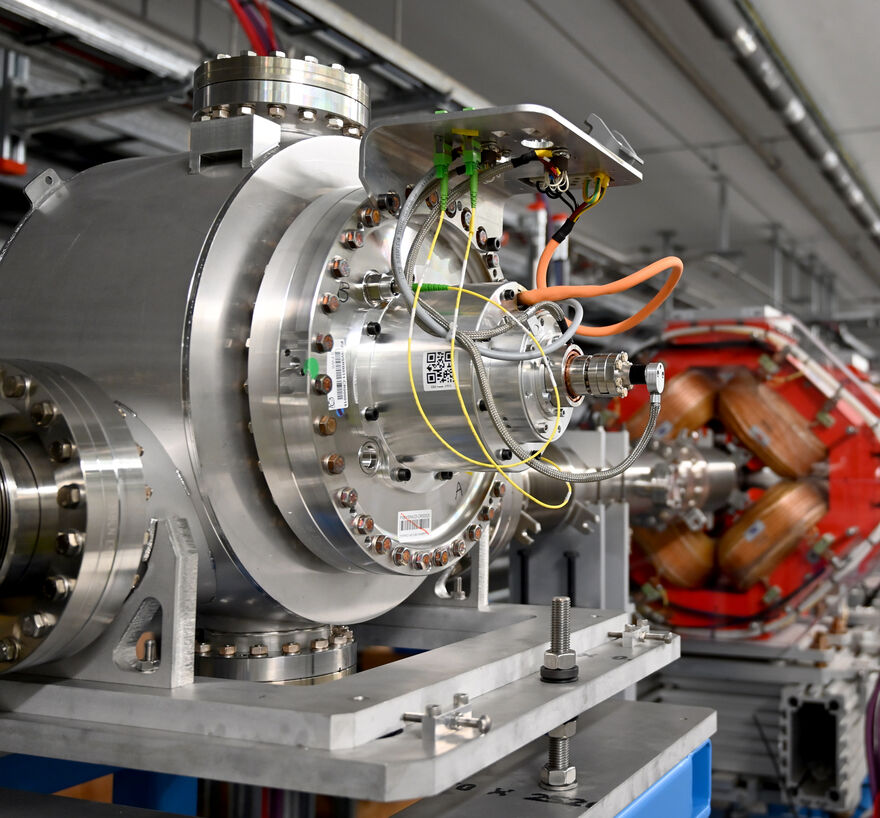

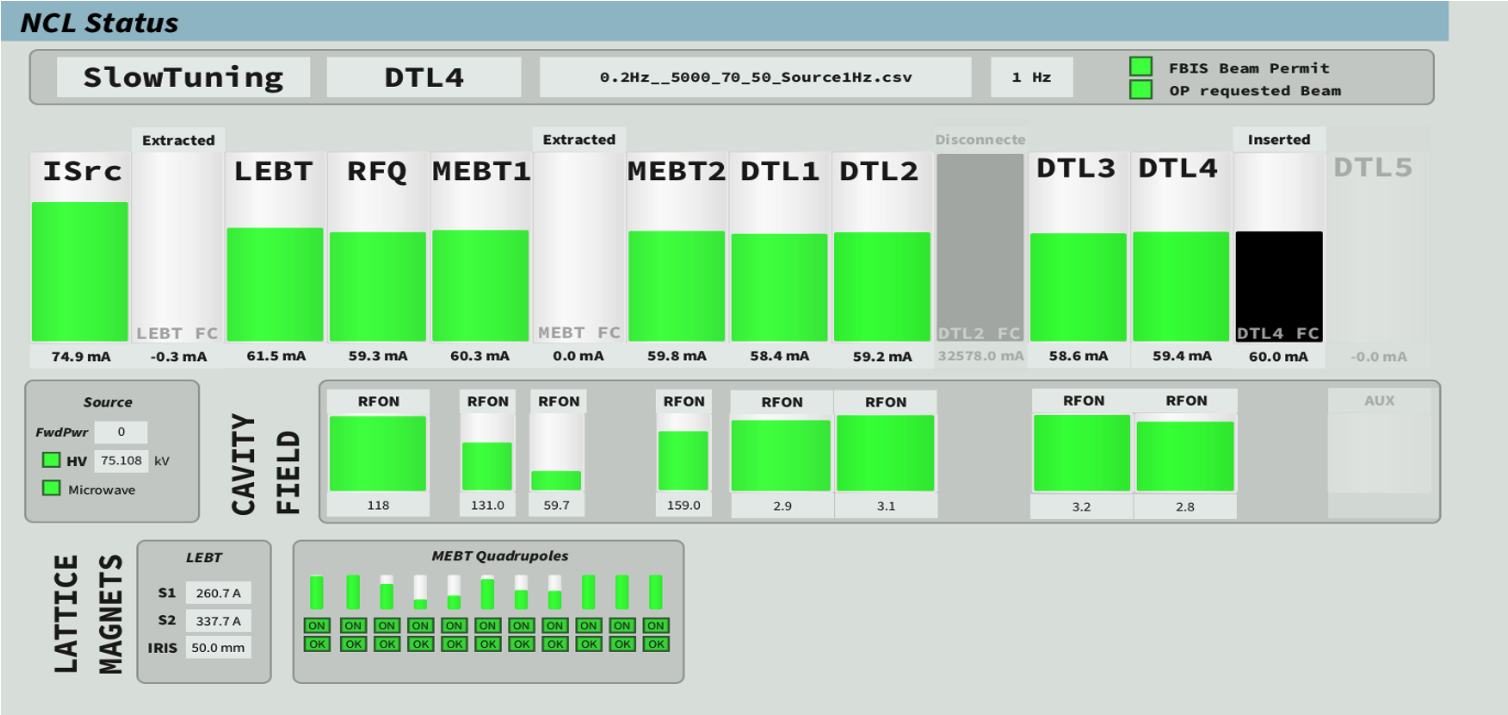

As part of this mission, ESS has successfully completed the installation of Beam Current Monitors (BCMs) in the entire accelerator, from the Ion Source to the Accelerator to Target area and dumpline to the tuning beam dump. This is a vital achievement for ensuring precise control and safe operation of the accelerator.

ESS is designed to be a state-of-the-art facility to produce neutrons for a wide range of scientific applications. To achieve this, the accelerator will operate with high precision and reliability, making Beam Instrumentation (BI) crucial. By providing precise control and real-time monitoring, these diagnostic tools ensure that the proton beam remains stable and safe throughout its journey. The complete BI suite consists of over 500 systems of more than 20 unique types, strategically placed along the beamline to monitor and control various parameters of the proton beam, ensuring its stability, safety, and overall performance.

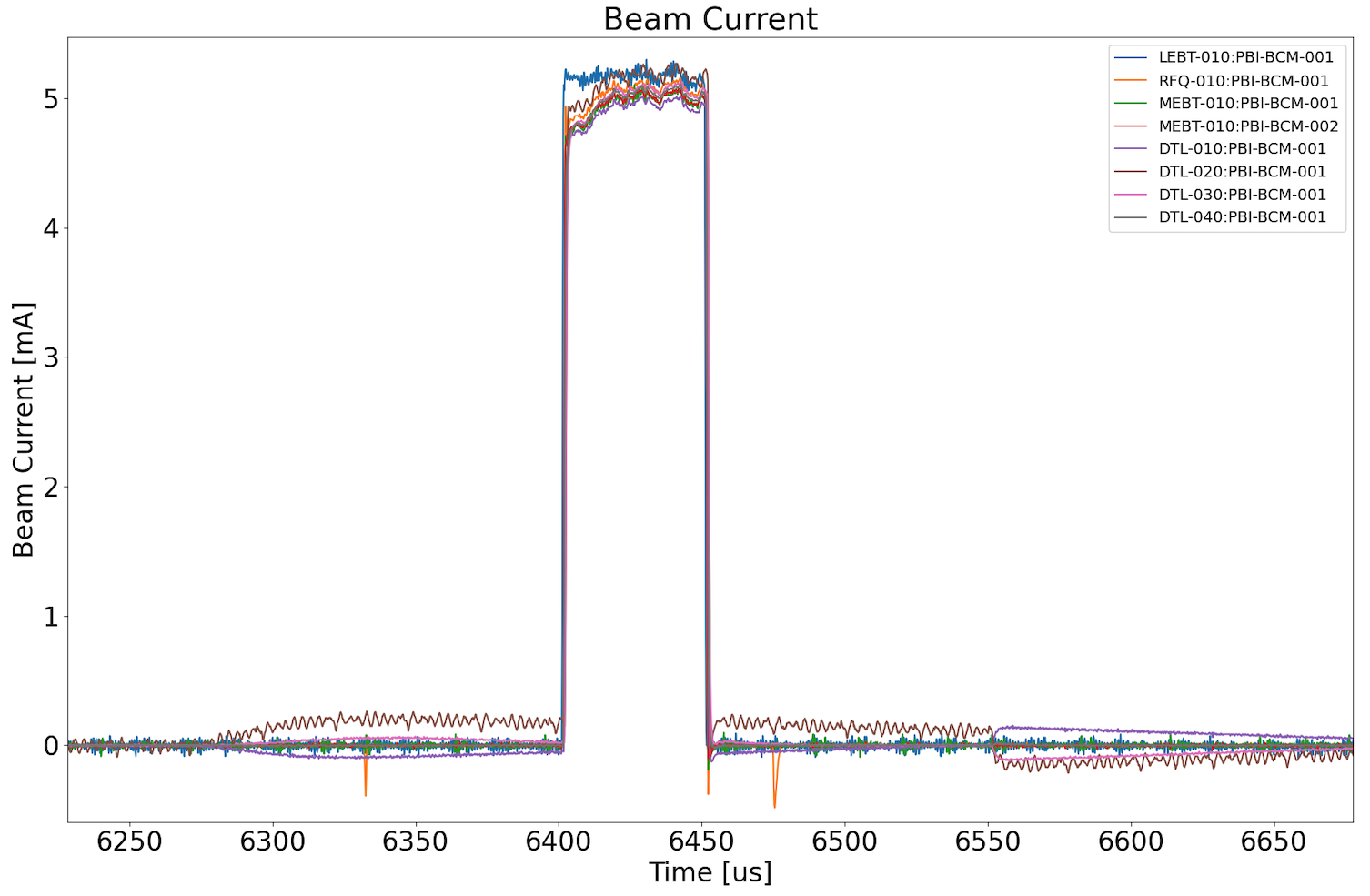

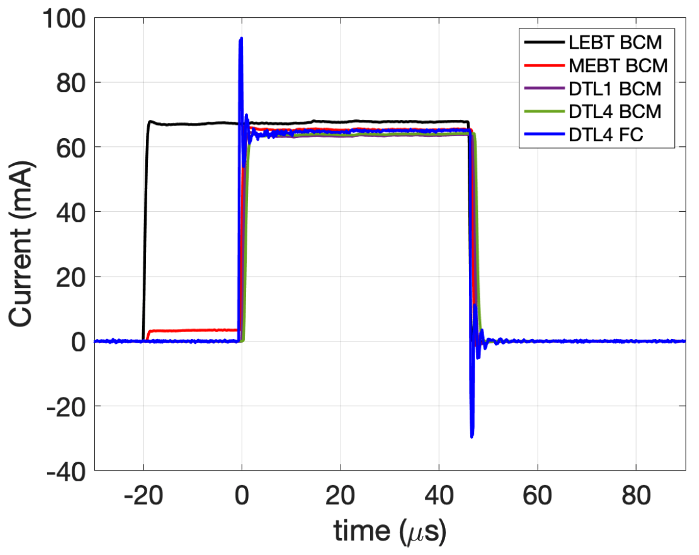

Beam Current Monitors (BCMs), alongside other instrumentation systems such as Beam Loss Monitors (BLMs) and Beam Position Monitors (BPMs), play a central role in the operation of the ESS accelerator. BCMs provide real-time measurements of the proton beam current, allowing for fine-tuning of the accelerator to maximise performance while protecting critical components from potential damage. BCMs also perform differential beam measurement using several differential pairs. The differential current from each pair shows how much beam is lost from one location to another along the linac. This will then be used for beam loss analysis and machine protection purposes. With the BCM and other BI systems, the ESS team will be prepared to monitor and control the beam with precision as the facility approaches full-scale operations.

As ESS moves towards full operational status, reliable beam instrumentation will be key to achieving the facility's goal of delivering Beam on Target, which will in turn trigger the spallation process, releasing neutrons for groundbreaking scientific research.