The Radio Frequency (RF) team has recently completed the installation and testing of all RF systems for the 2 MegaWatt (MW) power scope at ESS. This includes the installation of over 91 high-power RF systems, with all equipment certified and ready for accelerator operations. This accomplishment marks the culmination of years of hard work by the RF team and many other divisions, in collaboration with several European In-Kind partners.

The installation and testing of all RF systems for the 2 MW scope have been successfully completed. This means the entire RF system required to commission the accelerator, is now operational and certified for use. The first RF system to be installed and signed off for operation was for the RFQ back in 2021 and through a huge effort by the RF Team and colleagues across the organisation. The last system was installed and completed testing in September 2024.

The RF systems are currently being used for warm coupler conditioning. This process ensures that the couplers, which transmit the RF power into the cavities of the cryomodules in the accelerator tunnel, can handle the high-power RF signals safely and efficiently. Following the warm conditioning, the next step will be cold cavity conditioning, where the system will be tested under cryogenic conditions to ensure that the cavities themselves can perform optimally when cooled to superconducting temperatures.

The RF systems will supply the power needed to accelerate the proton beam, with the goal of a 2 MW average power capability on the Target. As ESS is a pulsed source, where the power is essentially turned on and off 14 times per second to accelerate pulses of protons, this means that the installed peak RF power capability exceeds 100 MW. To give a sense of scale, this is equivalent to switching on and off more than 50,000 household kettles at the same time, 14 times per second.

The RF power generated is transmitted to the cavities, which accelerate the proton beam. Each cavity requires precise timing and control to ensure that the protons are accelerated to the correct energy level. This is achieved through a combination of low-level RF (LLRF) control systems, which manage the phase and amount of RF power, and high-power systems such as klystrons, which deliver power in the range of 1.5 MW or 3 MW, depending on the configuration.

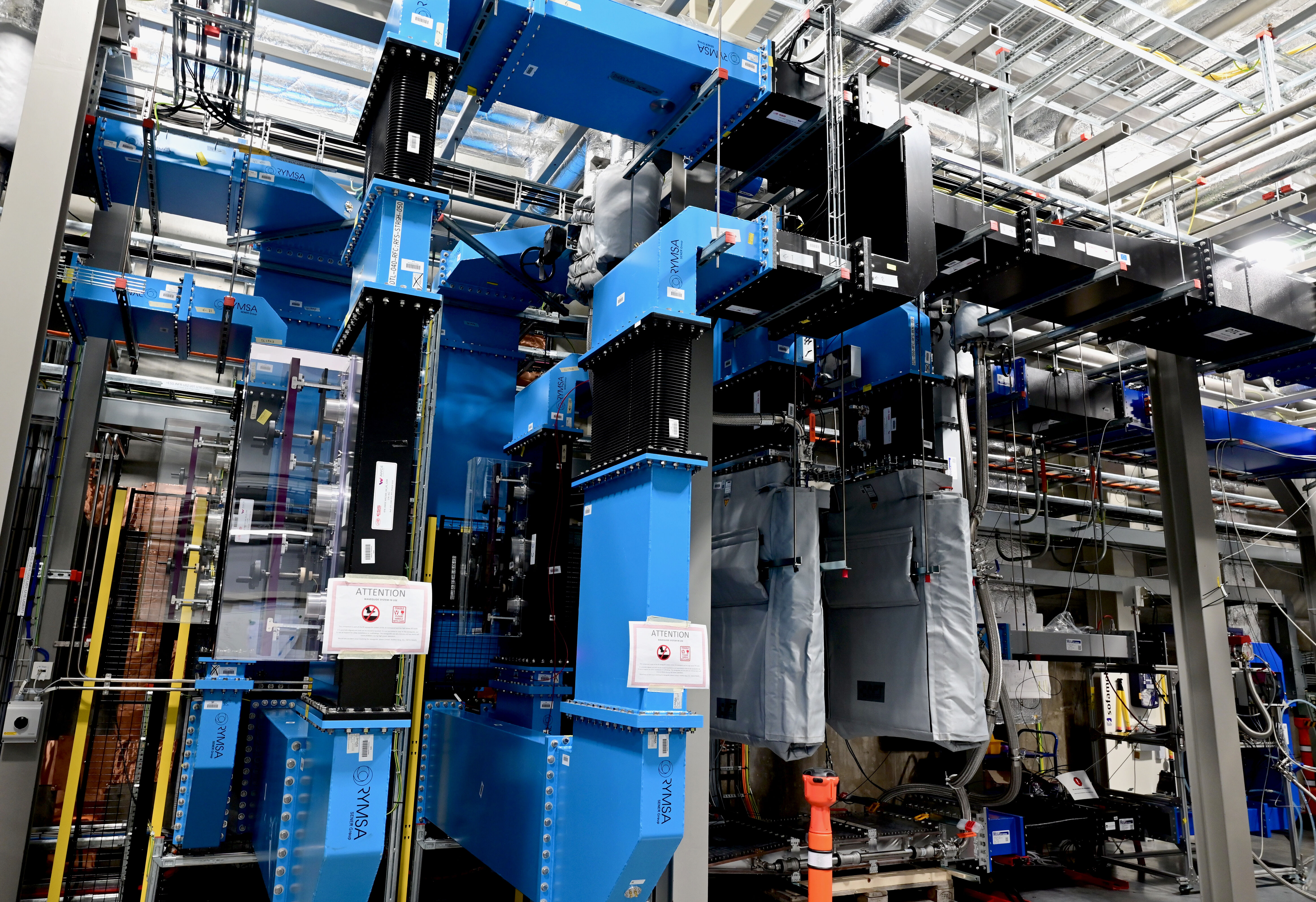

In total, the system includes six 3 MW klystrons, 56 1.5 MW klystrons, and 26 spoke RF systems at 400 kW. The installation involved placing over 24,000 cables, all tested and labelled, as well as laying out 5 km of waveguides, secured with more than 500,000 bolts. Along the gallery there are approximately 800 racks, with around 400 of them dedicated to the RF sub-systems necessary to drive the proton beam.

This ambitious RF installation is a massive undertaking that requires expertise from various groups within ESS, including Accelerator, ICS, Engineering, Vacuum, and Administration teams. The completion would not have been possible without the contributions of multiple In-Kind (IK) partners from laboratories in Poland, the UK, Spain, and Hungary. These partners have been instrumental in providing mechanical supports, waveguides, control systems, and delicate RF components. Their contributions range from low-level RF systems operating at milliwatt levels to klystrons producing megawatts of power.

With the completion of the RF installation and certification, the next major goal is to proceed through the final stages of conditioning and testing, leading up to Beam on Dump and later, Beam on Target. Each phase brings ESS closer to full operational status, where the proton beam will be delivered to the Target for neutron production and subsequent scientific research.

Installation and Testing Process for RF Systems

Each of the 91 RF systems has undergone the following installation and test steps:

- Pre-inspection: Inspect and test all equipment and sub-systems in the lab before installation.

- Rack Installation: Install and energise equipment for each RF system.

- System Installation: Install all power sources, klystrons, waveguides, cabling etc.

- Low-Power Testing: Set up all parameters, test full system connectivity, check interlocks.

- High-Power Testing: Operate all systems, from mains power through to the RF power for the cryomodules. Test power supplies, modulators, amplification stages, controls, and distribution from the RF Gallery to the tunnel. Evaluate RF signal quality, and ensure all specifications are met.

- Low-Level RF (LLRF) Test: Check and ensure the power and phase of the RF signal is optimised for the accelerating structures in the tunnel.

Waveguide Certification: Certify the waveguides to ensure safe and correct delivery of RF power without leakages and interference with other sensitive equipment.