Key technical components for the target have been delivered to ESS as part of Spain’s contributions to the facility. The target wheel, shaft and drive unit have been developed and manufactured by in-kind partner ESS Bilbao and will be installed at the core of the ESS Target.

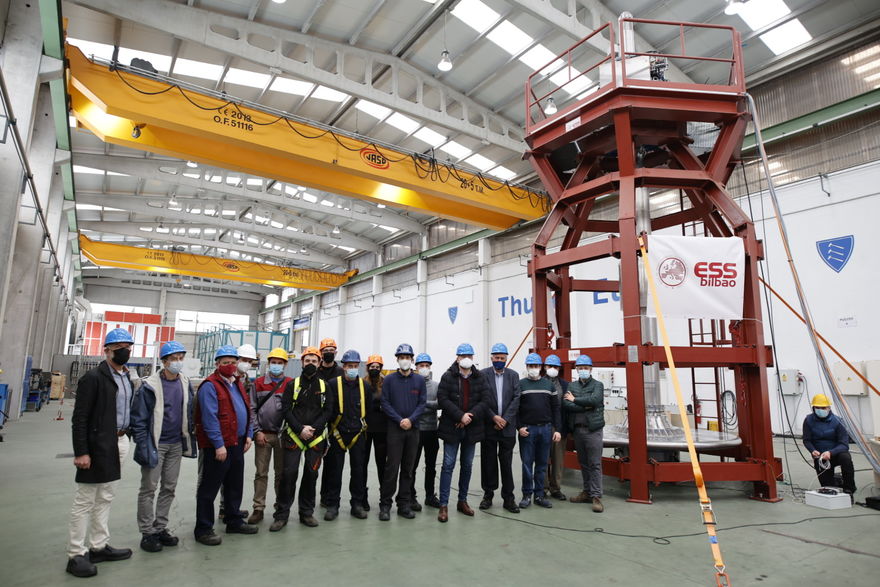

After successful final tests of the assembled target wheel, shaft and drive unit in the north of Spain, these fundamental technical components have been transported by special trailer across Europe, arriving on the ESS site this morning. The target system components are an important contribution from Spain, provided through ESS Bilbao and its industrial suppliers AVS, Nortemecánica and Thune Eureka. Spain is an essential contributor to the construction of the international research infrastructure, and has been strongly engaged in the ESS project since the start.

“Spain, with its important neutron research community and long and deep commitment to building the world’s leading research facility using neutrons, is a key member country for ESS,” said Helmut Schober, ESS Director General. “The target wheel, shaft and drive unit delivered today by our in-kind partner ESS Bilbao are proof of Spain’s advanced technological and industrial capacity.”

All Spain’s in-kind contributions to ESS are managed by the centre for neutron technologies ESS Bilbao, which for more than ten years has been an essential partner in the construction of the next-generation neutron source. ESS Bilbao is responsible for the optimised design, manufacture and delivery of the novel ESS target system, as well as other important elements of the facility, such as the Medium Energy Beam Transport for the accelerator and the MIRACLES instrument.

"Our researchers and science industry will benefit from the in-kind contributions delivered by ESS Bilbao to the world-leading research facility ESS, and these deliveries positions Spain as a driver of European science,“ said Mario Pérez, ESS Bilbao Executive Director. “The target system delivery is a milestone made possible thanks to our Industrial partners AVS, Nortemecánica and Thune Eureka, in excellent collaboration with our team and ESS.”

The multi-disciplinary research facility ESS, based on the world’s most powerful neutron source, will provide unique research opportunities for thousands of scientists from all over the world, benefitting the development of better batteries, new medicines and more sustainable materials. ESS has 13 member countries, that together fund and build the next-generation research infrastructure, to a large extent through in-kind contributions in the form of technical equipment, services and personnel.

“Participating in the design, manufacture and testing of the target system for the leading neutron research infrastructure in Europe has validated ESS Bilbao as an international benchmark for target technologies,” said Fernando Sordo, Head of the Target Division at ESS Bilbao. “Thanks to the skills and efforts of our hardworking team, we rose to the challenge that we took on.”

At ESS, the neutrons needed for research will be generated in the spallation process, when the target consisting of the neutron-rich material tungsten is hit by an accelerated proton beam. The rotating helium-cooled ESS tungsten target wheel is a novel design, developed specially to meet the high neutron flux requirements of ESS, which will deliver more neutrons for research than any other similar facility in the world. The target wheel measures 2.5 metres in diameter, weighs 4 tonnes and contains 7.000 tungsten bricks.

“Our very competent colleagues at ESS Bilbao and their suppliers have, in close collaboration with ESS, fine-tuned the design and manufacture of the novel ESS Target Wheel,” said Ulf Odén, ESS Work Package Manager Target Systems. “After years of design discussions, calculations and an extensive number of tests, it is extremely gratifying to see this first-of-its-kind target system finally arriving on the ESS site today.”

Before installing the target wheel, shaft and drive unit inside the Target Monolith Vessel, the components will undergo thorough testing in the ESS Mock-Up Test Stand on site, in technical tests that will continue until the end of the year.