The majority of the quadrupole focusing and steering corrector magnets, crucial for beam operations in the ESS accelerator, have been successfully tested and are ready for operations, taking ESS another step closer to the Beam on Dump and Beam on Target milestones.

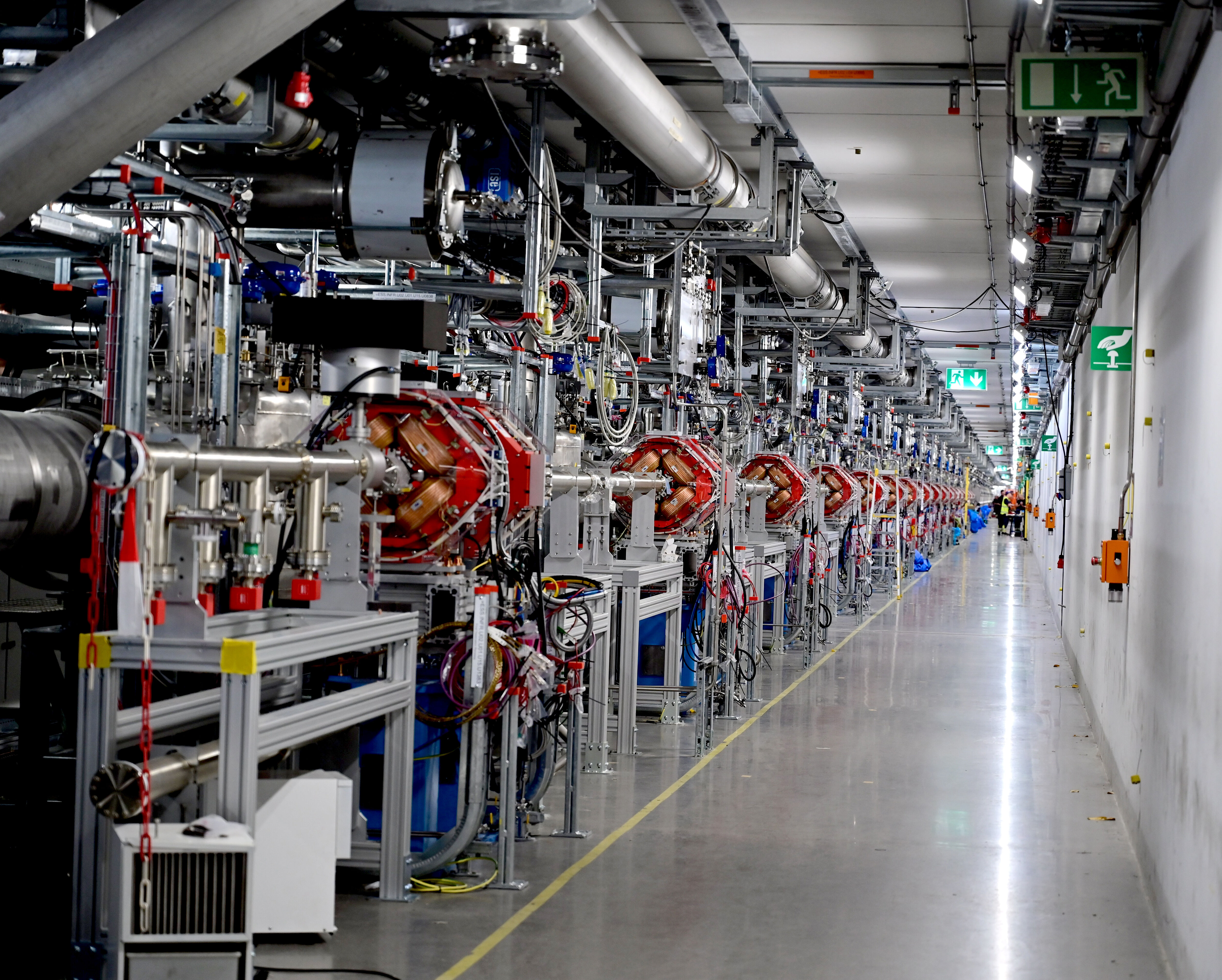

To guide, steer, and focus the proton beam, numerous magnets are installed along the accelerator tunnel — two quadrupoles and one dual plane corrector between each cryomodule, as well as upstream in the contingency area and the Accelerator to Target (A2T) section. In total, there will be 139 quadrupole magnets and 71 corrector magnets. The ESS vacuum team is responsible for connecting the magnets to the cryomodules and the vacuum chambers along the linac, including those placed between the cryomodules in the medium and high beta sections, and also the dipole bending magnets in the A2T section, which will be tested during the coming autumn.

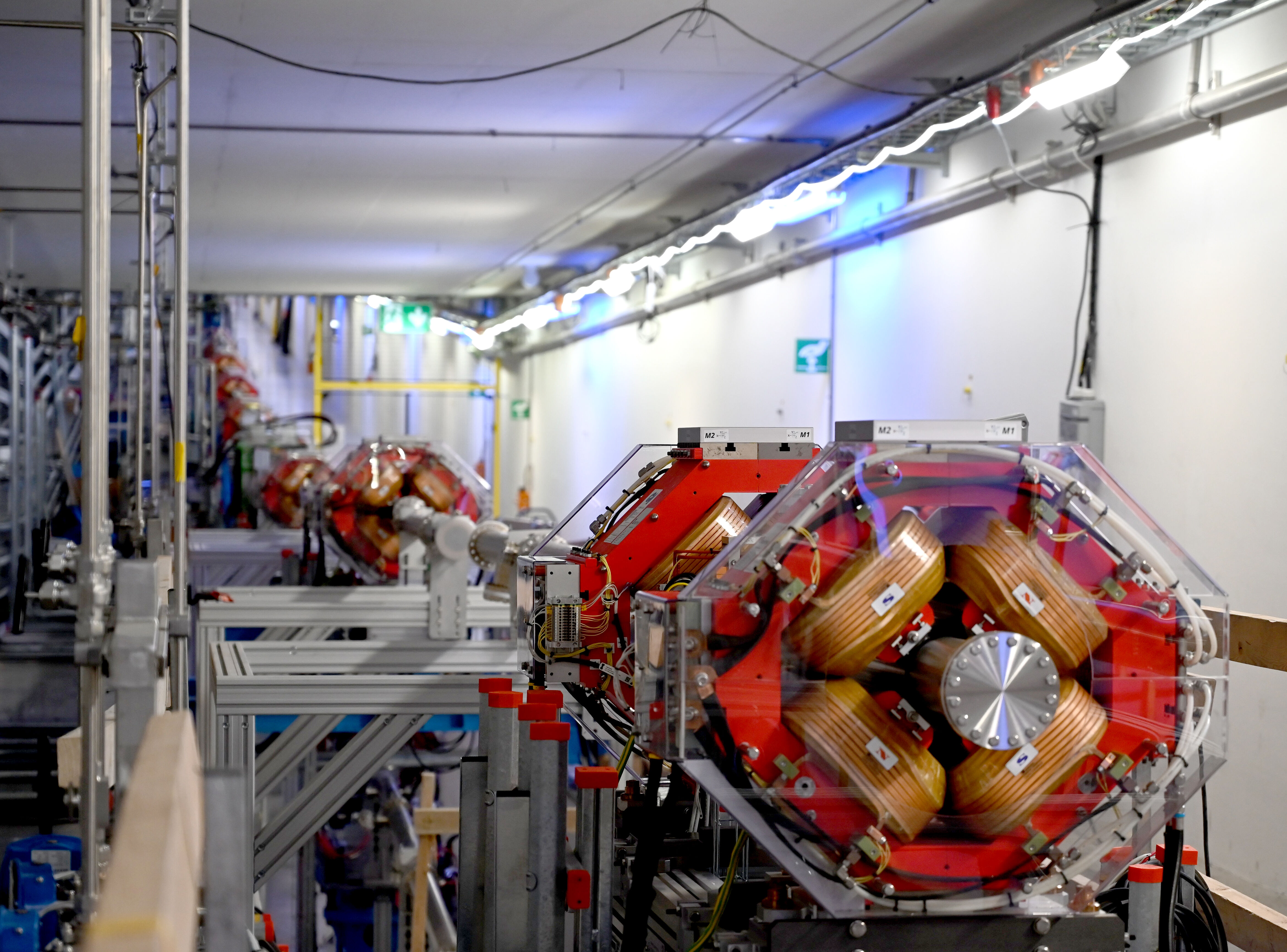

The beam, consisting of bunches of positively charged protons, tends to blow itself apart. To keep it constrained as it moves forward, magnetic fields are applied along the way. The quadrupole focusing magnets, arranged in pairs, compress the beam both horizontally and vertically, ensuring it moves from the start of the accelerator to the target without any losses.

So far, 111 quadrupole magnets and 57 corrector magnets (80%) have been fully installed and tested, ready to be handed over to operations. The remaining scope includes the magnets positioned between the cryomodules installed in the high and medium beta section.

Local tests, verifying the power supply performance, were followed by an integrated testing phase where the power supplies are connected to the magnets and all interfaces, including EPICS controls and machine protection system. The testing process involved rigorous assessments of the magnets' performance under operational conditions, ensuring they meet the required standards in terms of electrical installation and requirements in terms of current and magnetic field.

Next steps will include preparations for initial beam operations.

All the magnets for the ESS Accelerator were supplied by Elettra through the In-Kind partnership with INFN, Italy. They are part of the so-called Linac Warm Unit, manufactured and assembled by STFC, UK, and include beam diagnostics equipment from DESY, Germany. Linac Warm Units exemplify the true collaboration between ESS and its European in-kind partners.