Activity in the ESS accelerator tunnel has reached new highs - and lows - as parts of the ESS Cryogenic system are put through their paces, being cooled down, for the very first time, to temperatures as cold as outer space.

As part of the testing and commissioning phase of the ESS cryomodule Test Stand (TS2), the cavities of the ESS cryomodule prototype were recently cooled down for the very first time, using Helium, to an operating temperature of 2 Kelvin (-271 degrees C).

Head of ESS Cryogenics Section, Philipp Arnold explains, “There are two cryogenic circuits: in the first stage of testing, we completed a cool-down of the first circuit – the thermal shields of the cryomodule and cryogenic distribution system, and once this was stable, we parked the shield at ~40 Kelvin”. He adds that cooling the thermal shield down to ~40 Kelvin (approximately -230 degrees C) took about 20 hours.

"The ESS Superconducting Radio Frequency (SRF) team, which includes technical specialists from Poland’s IFJ Pan Krakow, proceeded to monitor and analyse the temperature data, and when it was confirmed all was stable, we proceeded to cool down the second circuit - the more delicate 4K circuit, to reach a stable pressure and a stable temperature. The second circuit cools to an eventual 2 K (-271 degrees C), which will be the operating temperatures for the Radio Frequency (RF) cavities,” Philipp added.

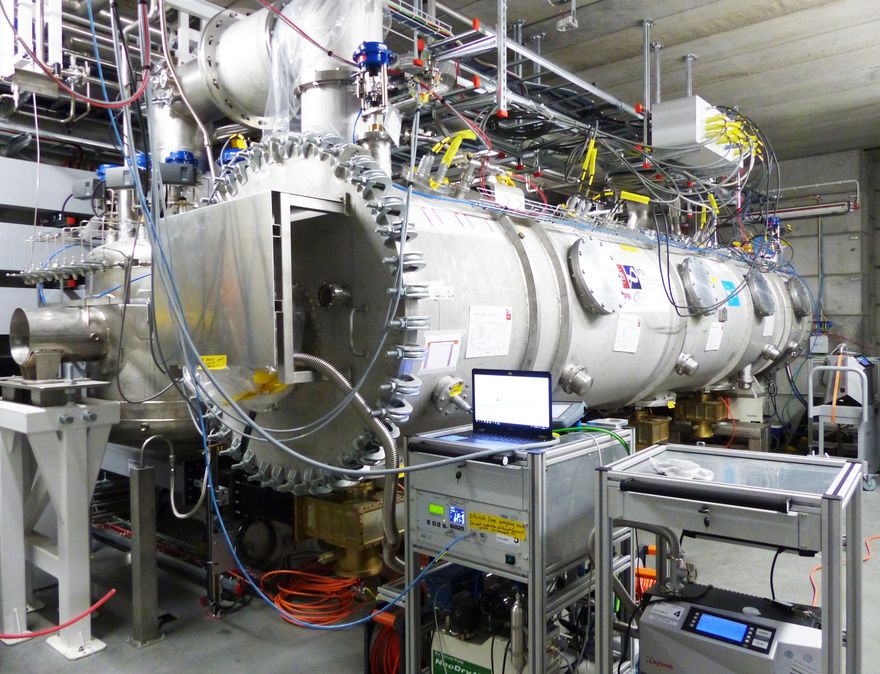

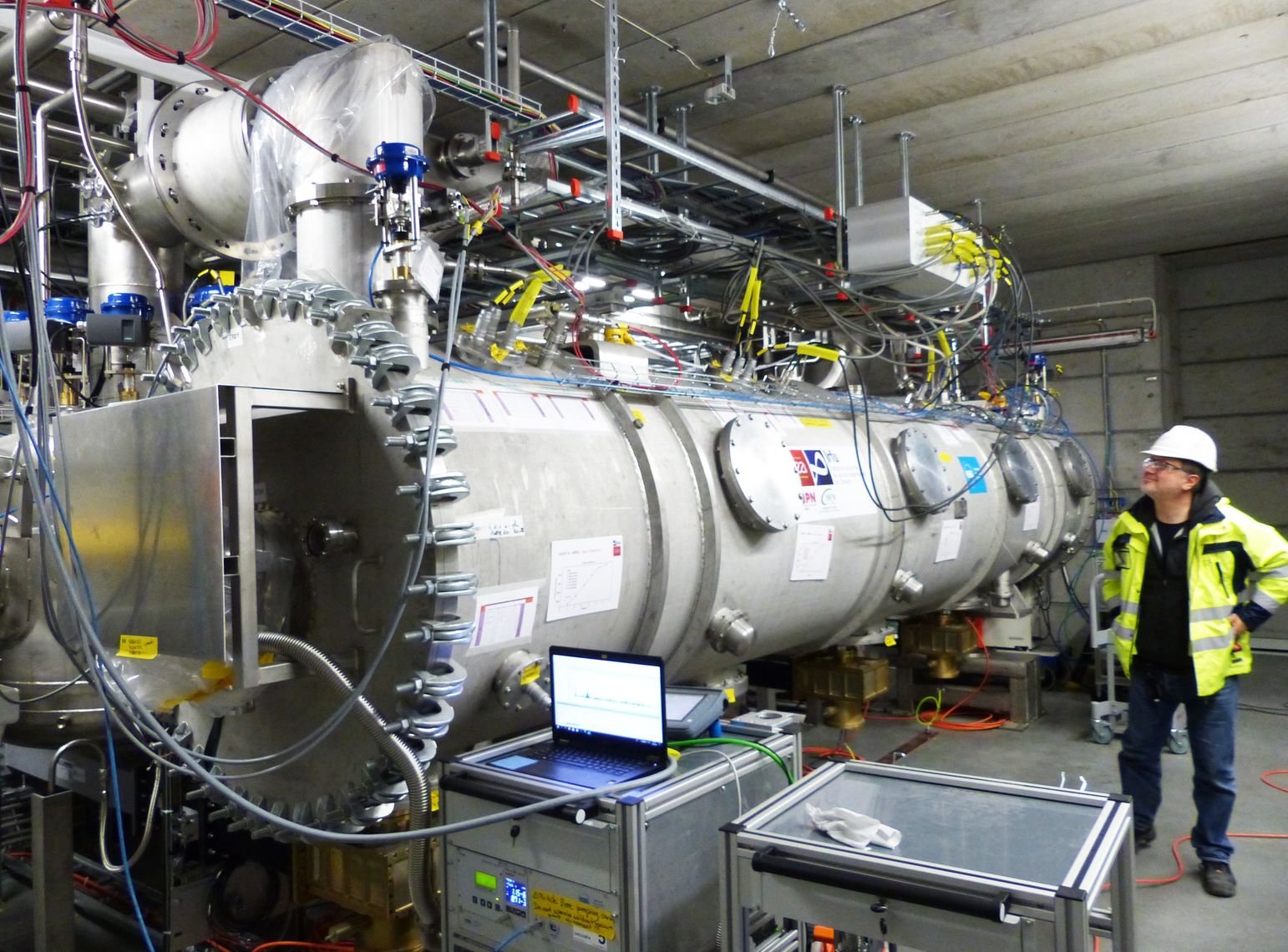

The Test Stand Bunker

The cooling operation is being carried out in TS2, in the klystron gallery, while all data is controlled, monitored and analysed from the Local Control Room by staff from the ESS Cryogenic Section, SRF and IFJ PAN teams.

“TS2 provides all the utilities, controls and a radiation shielding bunker for the cryomodules,” explains ESS Machine Section Coordinator for TS2, Wolfgang Hees.

In the past eight years, Wolfgang has led the design, construction and commissioning of TS2 in the G02 Gallery Technical Area, which is coming into full operation with the current activities, marking a visible success in the deployment at ESS of the infrastructures needed to receive and take ownership of the critical ESS accelerator components delivered from ESS In-Kind Partners.

“It is this infrastructure that ESS will use for testing various components - such as cryomodules, but also RF power sources - before finally positioning them in their places in the accelerator tunnel and gallery,” confirms Wolfgang.

"The RF cavities are very delicate devices whose functionality and performances can easily be compromised," explains Philipp. "They operate at a very low pressure, so you have to very carefully control the pressure and also monitor the temperatures with great accuracy and stability in the entire module. If the pressure gets too high, one could inadvertently deform the cavities, so, securing a homogenous temperature distribution, and critically, that a correct pressure is maintained, is very important – both for performance reasons and for avoiding potential damage.”

Where the Helium comes from

The cryomodule prototype is connected to the Test and Instruments Cryoplant (TICP) in the ESS Coldbox Hall, which, in turn, receives its helium supply from the Helium Compressor Building on site. The helium is looped between TICP and the TS2 cryomodule.

When a stable helium level has been established, the system is pumped down to lower the pressure of the helium gas – which reduces the temperature of the liquid helium to the desired final temperature of 2 K.

Next steps

The testing that is being conducted now will be followed by acceptance testing and the validation of the maximum heat load by the Test Stand and Cryo team.

The prototype cryomodule that is being used for testing will not be placed in the tunnel, Philipp points out, explaining that the prototype serves the critical purpose of testing the systems and logic to secure that everything works as it should for the cryomodules that will arrive from ESS In-Kind Partners, the French National Centre for Scientific Research (CNRS) and French scientific institute CEA - responsible for the design and the assembly of the cryomodule, as well as, Italy’s Istituto Nazionale di Fisica Nucleare (INFN) and the UK’s Science & Technology Facilities Council (STFC) - responsible for the procurement of the Medium Beta and High Beta superconducting cavities, respectively.

The completion of the prototype cryomodule testing, which will, in the near future, include the use of the high-power RF systems delivered by the ESS RF Section, led by Morten Jensen, will mark the transition of the TS2 infrastructure into its steady operation mode. The testing facility will be handed over for operation to the SRF Section, in charge of the testing programme and the preparation of the cryomodules for tunnel installation.

“Every module and component that will go in the tunnel will need to be thoroughly tested. We will have time now to test and debug our processes and programmes with the help of the prototype, then, the first cryomodule will arrive later this Spring and, following that delivery, the rest of the cryomodules will arrive with a frequency of once per month. By then, everything will have to work very smoothly,” concludes Philipp.