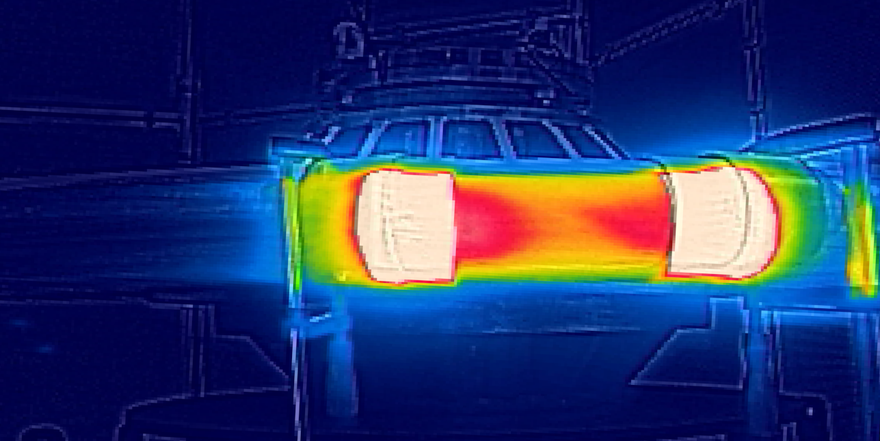

The ESS Beam Diagnostics and Target Division teams recently reported a significant achievement – they are now ready to coat the ESS Target wheel with a special luminescent material that will allow us to see where the protons hit the Target.

After years of work, the ESS Beam Diagnostics Team can proudly state that they are on track to enable ESS to actually see an image of the proton beam that travels down the ESS accelerator to hit the ESS Target.

This comes after four years of dedicated research and development led by the ESS Accelerator Division’s Beam Diagnostics section, in collaboration with the ESS Target Division, the ESS Science Directorate’s Sample Handling & User Laboratory (SULF), the ESS Spallation Physics team, and externally, together with the University of Oslo and Sweden’s University West.

Final tests took place at a thermal spraying company, TSE, in Malmö, overseen by University West, where the mock-up of the Target wheel was coated following the established industrial process that will be applied for coating the target wheel. The Beam Diagnostics team provided the necessary support to measure the amount of and secure the quality of the coating.

According to ESS Senior Engineer, Ulf Odén, who is also work package manager responsible for the delivery of the Target wheel, “Since the final target is a specially designed, one-of-its-kind component, the coating of the Target wheel mock-up was an important verification that the coating procedure will not damage the final Target. The coating of the Target dummy, the coating procedure and the final coating result, was a success and we are ready to proceed with coating of the final target once delivered from the In-Kind partner ESS Bilbao.”

The ESS Beam Diagnostics team has been working on this project together with University West since 2016, until they achieved the development of the full industrial process of coating the selected luminescent material. The team was put in touch with University West as a result of collaboration with the USA's Spallation Neutron Source who was strong supporter of this project, and knew University West had the relevant expertise.

“This has been one of the successful projects where the benefits of close collaboration within ESS and the usefulness of the chemical laboratories to the ESS project could be demonstrated,” said Monika Hartl, ESS Group Leader for SULF.

ESS Beam Diagnostics Engineer, Cyrille Thomas explains: “During that period of time, we were able to characterise samples in various places such as Oslo Cyclotron, ESS's Beam Diagnostics lab, and on site at ESS's laboratories. You can read more about the research that took place at the ESS labs in a recent article on the ESS website.

“What happened this week is the achievement of the first milestone of this project. It has been a really good collaboration, and the Beam Diagnostics and Target Division colleagues and I are really pleased, and look forward to the next steps,” Cyrille concludes.