The on-site chemistry and life science laboratories adjacent to the long instrument hall are operational at ESS since earlier this year, marking a significant achievement in building the facility.

The ESS laboratories that will provide neutron users with access to chemical and life science lab services for the preparation, modification and characterisation of samples for neutron scattering experiments went into operations this year, while installation works continue for additional laboratories adjacent to the two other instrument halls for the short and medium neutron instruments.

These laboratories also provide support for ongoing construction and operations of ESS, eg. analysis of materials; pH/conductivity measurements for the various water circuits, and more.

Building ESS together

The ESS lab infrastructure and facilities are an in-kind contribution to ESS from the United Kingdom, an important ESS collaboration partner, and have been provided by the Science & Technology facilities Council’s ISIS neutron & Muon source.

The ISIS Support labs have an excellent reputation across the international neutron scattering community and the ESS were keen to learn from their experiences in supporting neutron users with the best possible lab infrastructure and facilities.

According to Monika Hartl, Group Leader for Sample Handling and User Laboratory, “The reason why we have so successfully completed the installation in the E-buildings albeit Brexit and the Covid-19 pandemic, has been the close collaboration between the in-kind partners at STFC and ourselves.

“With the input from the Group Leader for the ISIS support labs, Marek Jura, and Senior Laboratory Technician, Sarah Langham, we have been able to streamline the project and strike a good balance between must-haves, especially at the beginning, and nice-to-haves. SFTC has also supported ESS with long-term loans of instrumentations, one of which is currently the most used instrument in our lab – the X-fluorescence machine.”

“I have really enjoyed working with the ESS Lab Group over the last five years,” shares Marek Jura, adding that “It has been a real team effort, where all members of both ISIS and ESS lab groups have been involved in the sharing of ideas and experiences, and it’s great to see it come to fruition.”

In addition to the UK’s contributions, lab equipment has also been received via other ESS members and in-kind partners. Estonia’s University of Tartu, have supplied two customised glove boxes for the Radioactive Materials Lab (RML). Installation of the RML is currently ongoing. These glove boxes will allow handling of activated, air-sensitive materials and are catered to the ESS needs, which will not only support the user program, but also be very valuable during the commissioning of the machine

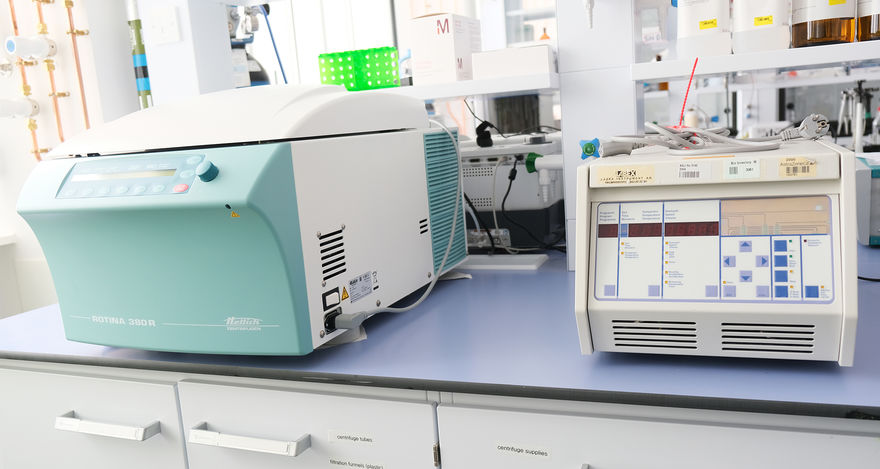

Something old, something new, something borrowed, something blue

In the ESS laboratories you will find everything you would expect from a chemical lab: measuring scales, stirrers, heating plates, pH and conductivity meters, water analysis, ovens/furnaces, ozone generator, centrifuges and a lots of glassware, but also analytical equipment, like a single crystal X-ray machine, spectroscopy instruments, a pycnometer, a scanning electron microscope, a microwave digestion instrument, a ball mill, a diamond saw, potentiostats, glove boxes, to name but a few items.

The equipment has come from various sources. Some are old, stable, trust-worthy machines adopted from other facilities, or bought second hand; some are brand new state-of-the-art pieces of equipment; while others are on-long term loan from our sister facilities around Europe. You will even find some equipment in an ESS shade of blue!

ESS Laboratory technician, Katrin Michel explains: “When we buy instruments for the user labs we generally check brands and models we have had good experiences with. However, if the method is unchanged we also look for second-hand deals to be able and buy more with the budget we have. This way, we broaden our analytical capabilities for the user labs.”

Sustainable science

“It’s good to see how the team is assembling labs with a range of both new and used analytical equipment. ESS has great potential to address society’s challenges related to climate and the environment - but true sustainability begins already in construction and procurement,” says Sindra Petersson Årsköld, Senior Advisor on policy, communication & strategy in the ESS Science Directorate.

“Making use of pieces of high-quality equipment that other labs no longer use is a great way to build sustainably for science. When the lifetime of the equipment is extended, the carbon footprint and materials consumption associated with a new purchase is postponed, and the equipment will serve the European science community for many years yet,” Sindra adds.

These labs will have an important role in sample preparation and characterisation when we have neutrons on our instruments. Right now, the ESS Sample and User Laboratory Facilities (SULF) team supports the construction and installation teams with element analysis, material optimisation and chemical investigations. For example, they have been performing water analysis for the cooling circuits as well as elemental analysis of construction and shielding materials. This is a joint effort with the materials experts in the Target Division.

Conducting real experiments in the ESS sample and user laboratory facilities

Earlier this year, the SULF team had the company of two post-graduate students from Lund University’s Faculty of Engineering (LTH), Emelie Wiklund and Anton Järild. They were at ESS conducting research at the laboratory in connection with their Master’s thesis on a luminescence material for the ESS Target, in collaboration with the Beam Diagnostics Team in the ESS Accelerator Division.

The goal is to develop an optimal flame-sprayed screen on the target to illuminate the proton beam position when it hits the rotating tungsten target wheel and capture an image of the beam. The image from each beam pulse delivered to the target is real timed analysed to verify the beam properties, with the aim to protect the target when measured properties are found to be outside the nominal beam envelop.

Their work will help ESS understand the manufacturing of luminescent material prepared for thermal spraying, which puts ESS in full control of the coating industrial process.

Anton explains: “When a material is exposed to radiation of this magnitude, there are many mechanisms occurring simultaneously that may be responsible for the decay of luminescence. We expose materials to external factors that simulate the target environment and study how they are affected. From these experiments, we can further understand their behaviour to tailor a suitable luminescent coating for the application.

According to Emelie, a regular day during their Masters’ thesis at ESS included collecting data and information from earlier studies at ESS and similar research facilities, working in the lab where we are performing different syntheses with varying parameters, studying relevant properties, and characterising the synthesised material.

“I am truly grateful for working right in the middle of front-line material research which will lead to ground breaking discoveries when ESS is in full operation,” says Emilie.

Anton adds that “performing our master thesis at ESS has been a great experience so far. Working alongside such experienced people is a wonderful opportunity to gain knowledge in materials science. It feels great to be a part of this world-leading science project”.

Emilie and Anton have since, successfully presented their Masters’ thesis, and their research project provides insights on the optimal composition of the material being sprayed on the target, as well as manufacturing of the material, and possibilities of producing such a material at ESS.

Next Steps

While the laboratories are ready for daily operations, commissioning of instrumentation and preparations to better support the ESS project are still continuing.

“We are expanding our capabilities and will be extending our suite of laboratory instruments while providing support to ESS. This in turn helps us prepare for supporting the user programme where everything has to be in place and well organised,” concludes Monika Hartl.