Conditioning of the first drift tube linac (DTL1) has started. This is a key milestone for the ESS Accelerator Division, and another important step towards the commissioning of the full machine.

The DTL section of the accelerator is designed and built by INFN (National Institute of Nuclear Physics), as part of the Italian In-Kind contribution to ESS.

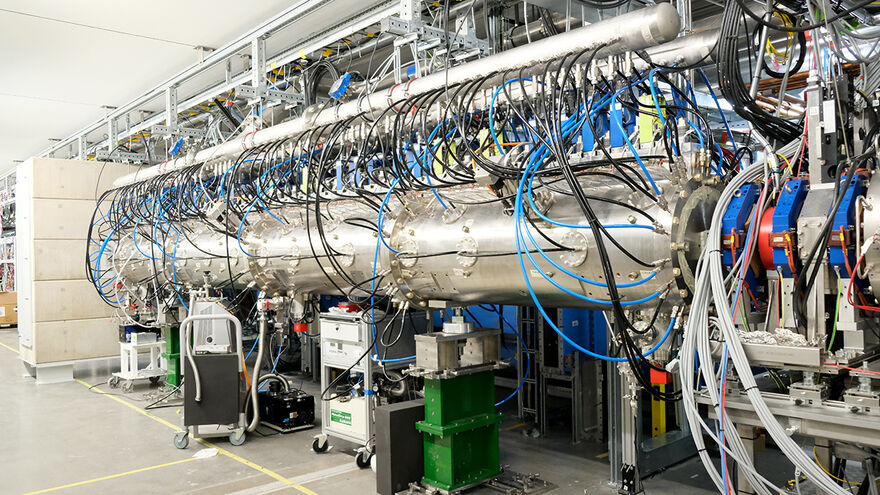

The Drift Tube Linac (DTL) section of the ESS linac will accelerate the proton beam from 3.6 to 90 MeV, which equals 40% of the speed of light. When fully operational, it will be the most powerful drift tube linac in the world.

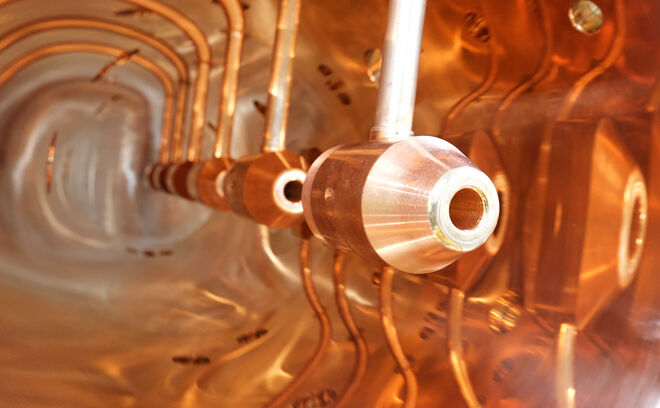

Inside the drift tube linac tank there is a sequence of accelerating gaps, allowing protons to gain energy each time they pass through a gap. The gaps are alternated with tubes, where the particles are shielded from the RF field, and they simply drift. Because the RF field periodically reverses its polarity, the beam drifts inside the tube to make sure that the beam always meets the field at the polarity giving acceleration.

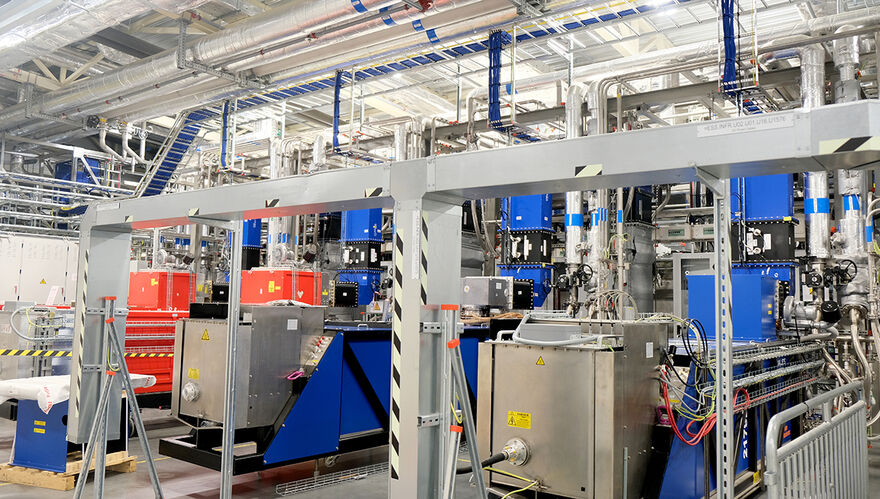

The five DTL tanks are an in-kind contribution of INFN to ESS. Designed by INFN-Legnaro and INFN-Torino, all the parts are produced and separately tested in Italy. Then everything is shipped to ESS and assembled and tuned by INFN staff in a dedicated workshop located in the ESS Klystron Gallery.

After all the checks have been passed and the tank has been installed in the linac, “RF fuel” is injected in the engine, starting the conditioning phase.

INFN is involved with ESS in all stages of the DTL, from design to installation, from RF conditioning until beam commissioning.

What is conditioning?

Conditioning is the process of gradually ramping up the radio-frequency (RF) power applied to the cavity until it reaches the power and stability required to accelerate the proton beam. Starting at a low power level, the power is then gradually ramped up to reach 1.2 MW, 3ms pulse and 14 Hz repetition rate – ready for beam operation.

During the conditioning, the performance of the RF system supplying power to the cavity and all its safety functions, the vacuum system and the water-cooling system, is also confirmed.

The conditioning activities are performed by members of the Front End and Magnets section of the ESS Linac Group with support from the ESS operations team and in-kind partner INFN.

What's next?

When the conditioning phase is completed beam will be accelerated from the Ion Source through the Low Energy Beam Transport (LEBT), the Radio-Frequency Quadrupole (RFQ), the Medium Energy Beam Transport (MEBT) and DTL1 up to a Faraday Cup (FC) installed at the end of the tank. In preparation for this, a Safety Readiness Review will be held.

The beam commissioning stage including DTL1 is expected to be completed this summer, after which three more DTL tanks will be installed and tested.

Once the fifth DTL tank is installed and tested, the RF conditioning will be carried out together with the rest of the Superconducting Linac before the first beam will be sent to the Tuning Beam Dump.