The crystal analysers in the BIFROST instrument have been successfully installed and precisely aligned in the spectrometer tank. These analysers are a key component of the BIFROST extreme environment spectrometer, one of the first instruments to go live at ESS, ready for first neutrons by the end of 2025.

Read more about this and other recent achievements for the BIFROST team below.

The recently installed analysers for the BIFROST instrument will be operated by utilising crystal diffraction to select neutrons with specific energies and wavelengths. This is achieved by the precise orientation of the crystal planes, allowing selected neutrons to be detected and analysed. This process provides detailed information about the properties of the material studied, enabling researchers to probe the internal dynamics of materials with unparalleled precision.

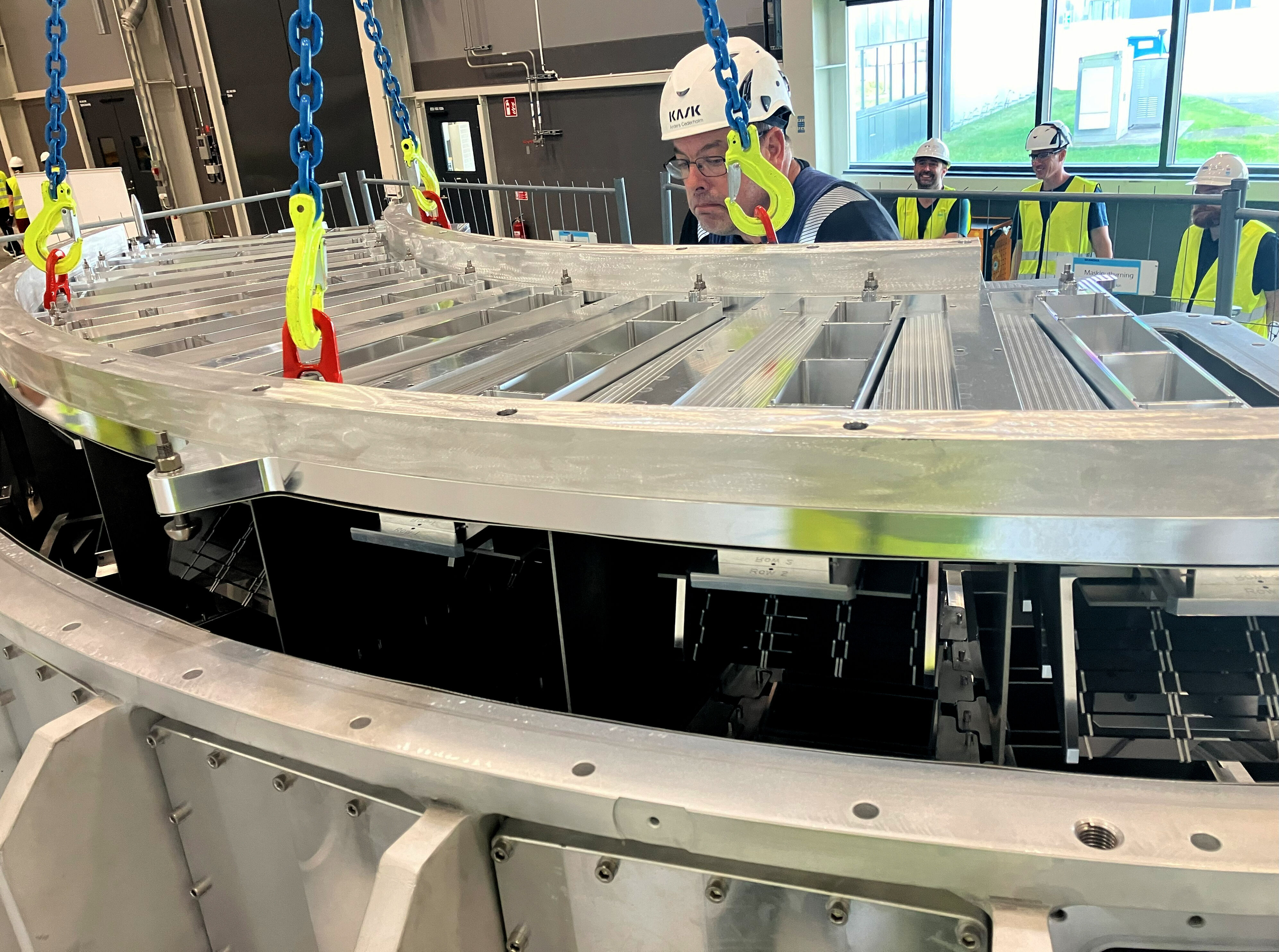

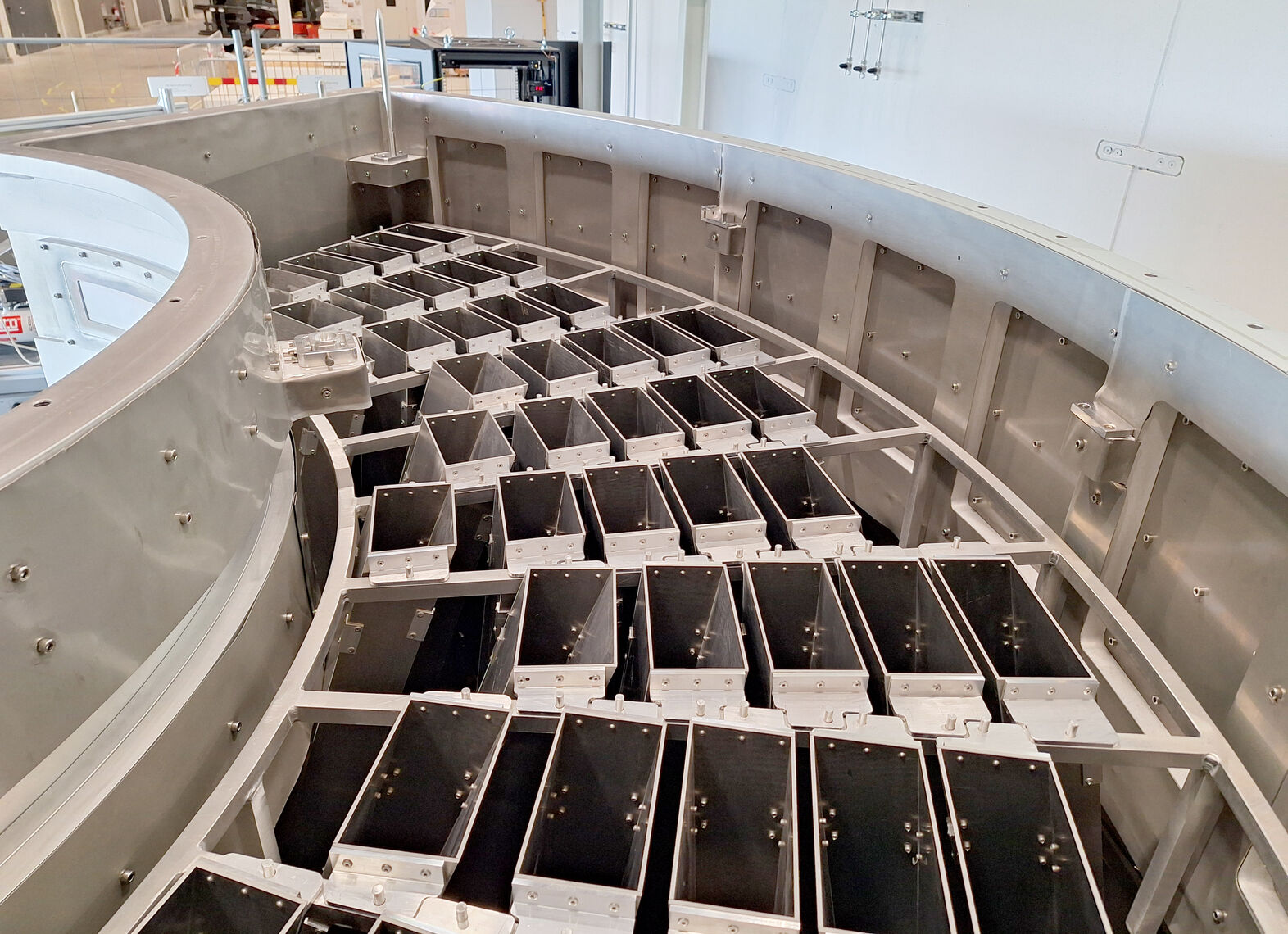

The crystal analysers were prepared in the workshop of Danish In-Kind Partner Technical University of Denmark ( DTU). Using high-precision machining, the components were aligned within 0.1 degrees on their holders. The crystals themselves were provided by Swiss partner Paul Scherrer Institute (PSI).

After delivery to ESS, a team from DTU and Copenhagen University assembled the analysers onto a frame in a cleanroom environment. The frame was then carefully lifted into place in a vacuum chamber on top of the spectrometer vessel. The ESS Survey, Alignment, and Metrology Team conducted the necessary measurements and ensured the alignment was perfect. Meanwhile, the detector modules, already installed underneath the tank, have undergone thorough testing to ensure optimal performance.

In addition to the crystal analysers and detectors, significant progress has been made on other components of the BIFROST instrument. The 160-metre-long neutron beam guide is already in place, connected to the Neutron Beam Port Insert with the Neutron Beam Window and Bridge Beam Guide (BBG) optics assembly. All four choppers, a fast pulse-shaping chopper as well as three additional ones have also been successfully installed. Additionally, the BIFROST beryllium filter has arrived for a successful SAT cooldown test, conducted in and facilitated by the sample environment lab and its staff. BIFROST lead engineer and project manager, Liam Whitelegg, led the concurrent installations.

Another significant milestone is the energisation of the Integrated Control System (ICS) racks for BIFROST, marking the first instance of permanent power in the instrument zone, which includes the cave and hutch but not yet the bunker area. This allowed verification of the technical network's accessibility in these areas, ensuring timing signals from the Klystron Gallery to the Long Instrument Hall are received, and activating Wi-Fi access points in the cave and hutch. This crucial step initiates the start of cold commissioning for BIFROST, focusing on testing its choppers.

This achievement has been a collaborative effort involving teams from Controls Infrastructure, Neutron Instrument Technology and Integration Support (NITIS), and the Timing System within ICS, alongside ESS Electrical, NSS Electrical, Choppers, and the BIFROST instrument team.

The next steps for BIFROST involve the installation of the spectrometer vessel onto the structure inside the shielding cave and the integration of all components within the cave, taking BIFROST closer to operational readiness. This integration effort involves most technology teams within the Neutron Scattering System (NSS) division as well as the ESS Data Management and Software Centre (DMSC), where the goal is to ensure that all components delivered can be integrated into the ESS experiment control systems and that the timed data for motor position and chopper positions can be properly stored in the data file. This helps to ensure that once neutrons come, focus will be on understanding the scientific performance of the neutron instrument as a whole, rather than getting individual components to work.

BIFROST is built in collaboration with five partners: