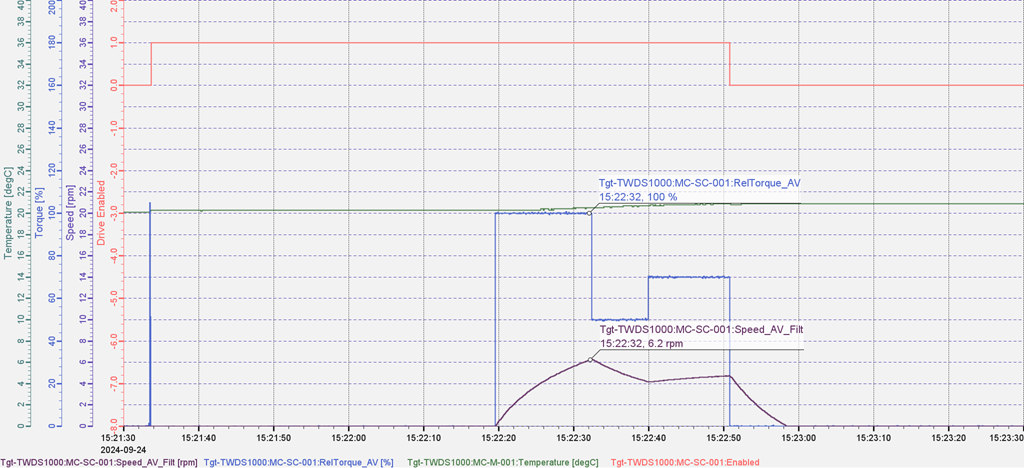

This week at the ESS site, the first-ever in-situ rotation of the target wheel took place inside the monolith vessel, marking another step towards the first proton-beam-on-target in late 2025. Over the next few months, testing will continue, gradually ramping up the speed and integrating additional systems.

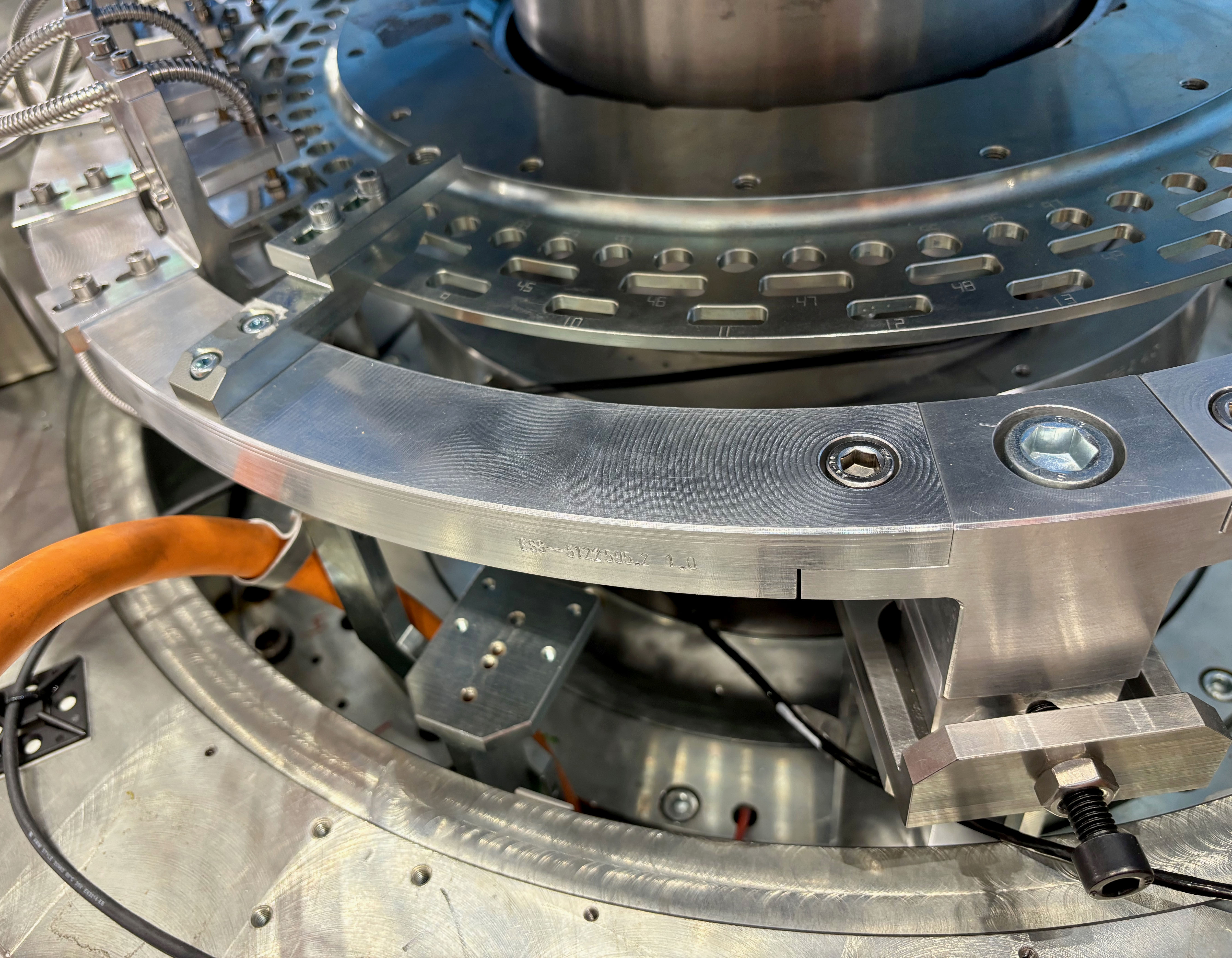

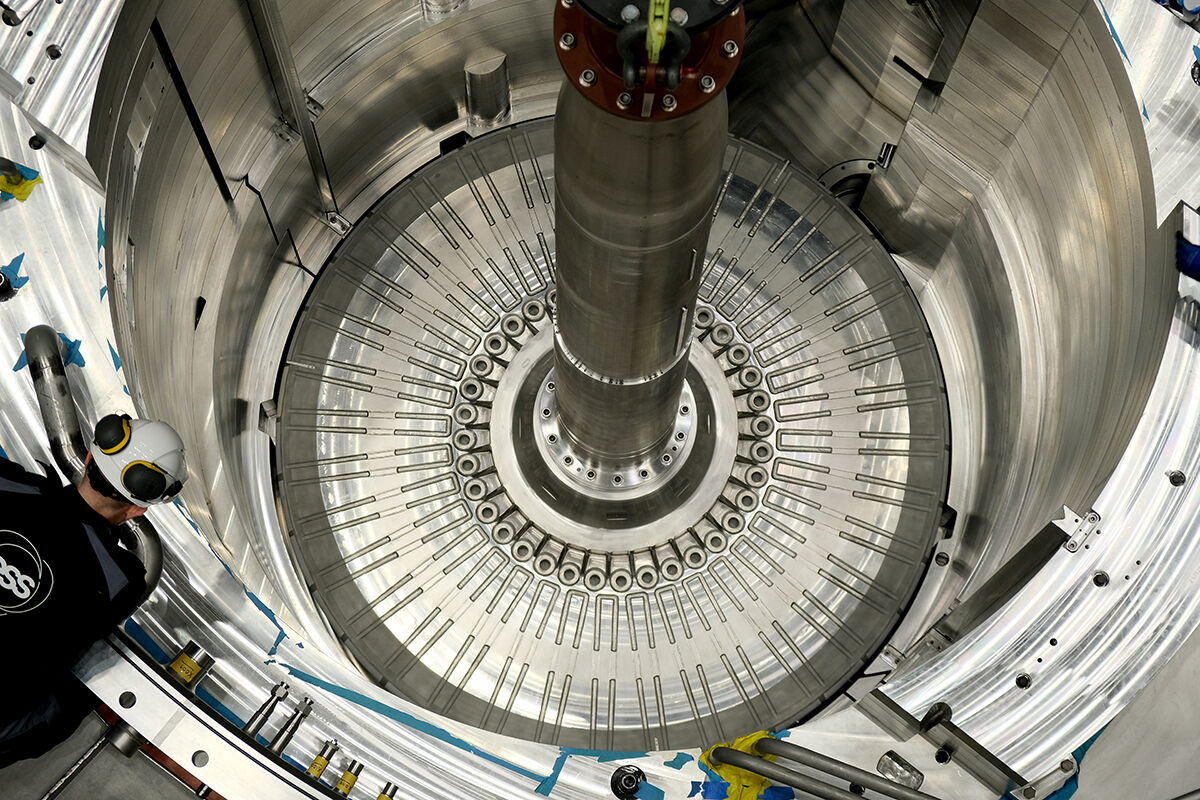

The target wheel, a key component in the spallation process at ESS, was delivered by the Spanish In-Kind Partner, ESS Bilbao, in 2022. Since then, it has been coated with a luminescent layer as part of the beam diagnostics imaging system and fitted with its shaft, drive unit (motor), and a rotary union for the helium cooling feed. The wheel has undergone rigorous testing in an on-site designated test stand, with lifting, handling, and rotation trials. This included a continuous 1,000-hour spinning test to ensure operational reliability.

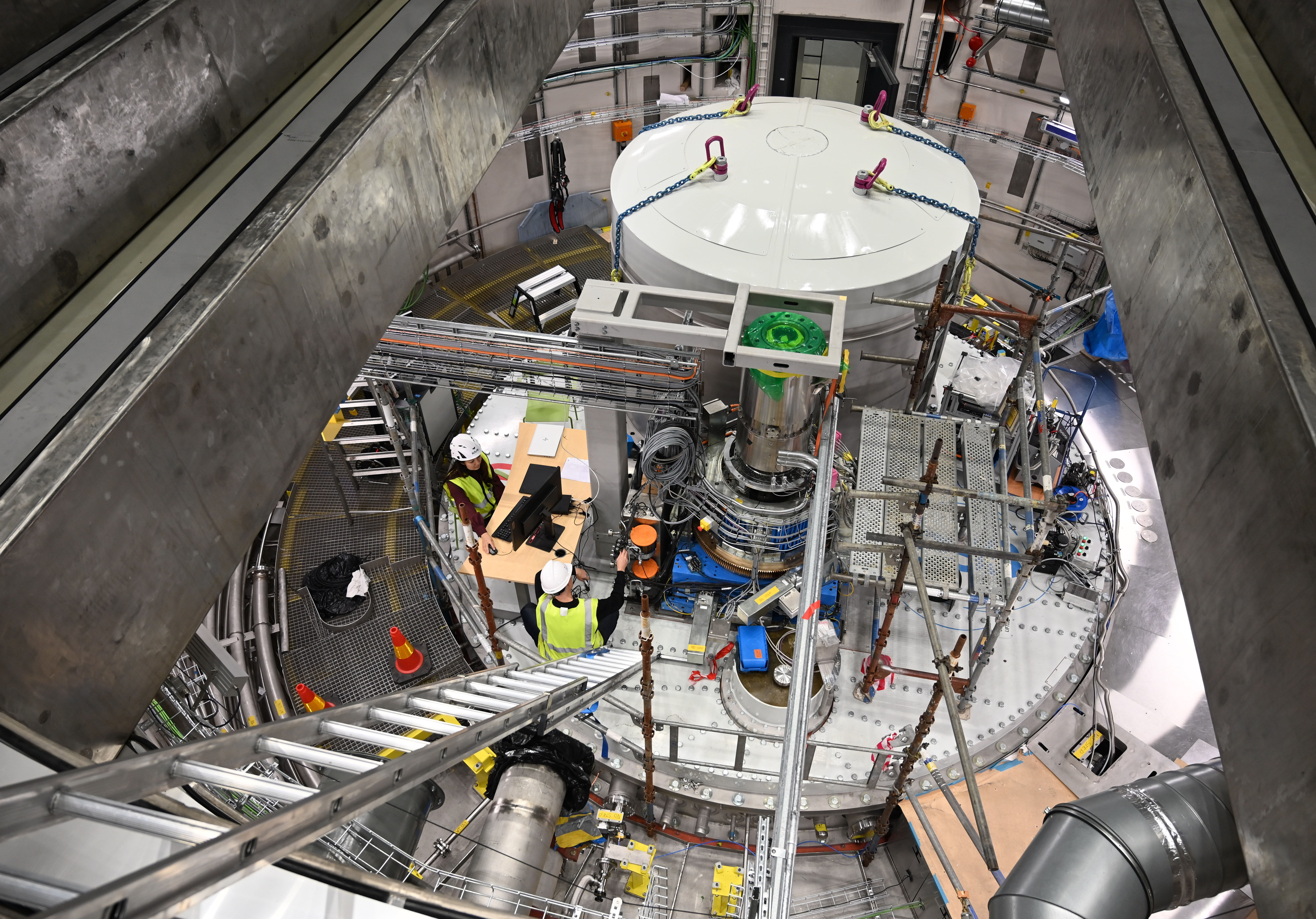

In November 2023, the target wheel was installed in its designated space inside the Monolith vessel, shielded by about four metres of stainless steel blocks. Simultaneously, the ESS target moderator-reflector plug was also installed adjacent to the wheel. See the video here.

In parallel with the target wheel preparations, additional critical systems have been integrated within the monolith, including piping for the helium circulator system and the commissioning of the cryogenic cooling system for the moderator. The monolith vessel’s large lid (head of the vessel) was placed in March 2024, followed by the installation of the moderator cap in May 2024. This sealed the monolith and enabled comprehensive vacuum leak tests over the summer.

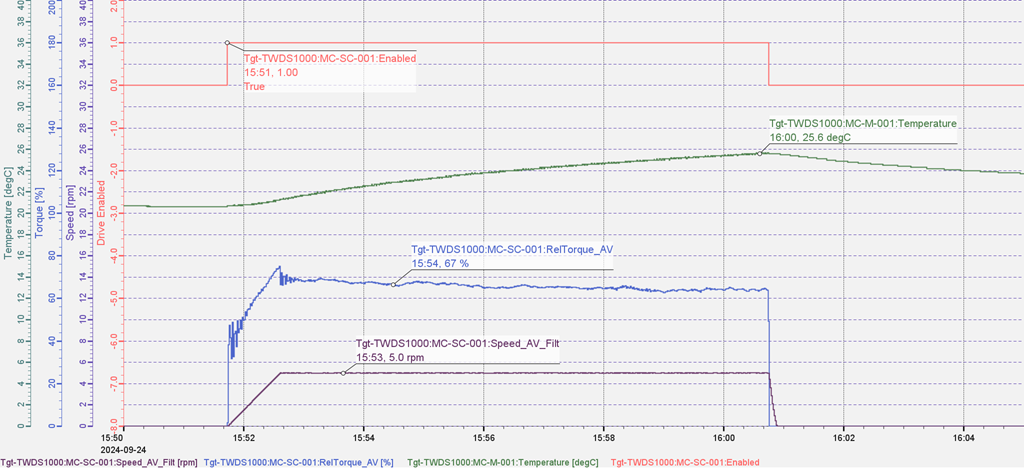

Recently, the ESS vacuum team successfully achieved the vacuum conditions necessary to operate the target station, which allowed the start of the now ongoing in-situ target wheel rotation tests.

The rotation tests started this week will gradually ramp up to the target wheel's nominal speed of 23 1/3 rotations per minute. This speed synchronises with the proton pulse and the ESS timing system ensuring the 36 segments of the target wheel are hit at regular intervals, maximising the number of neutrons released for scientific use.

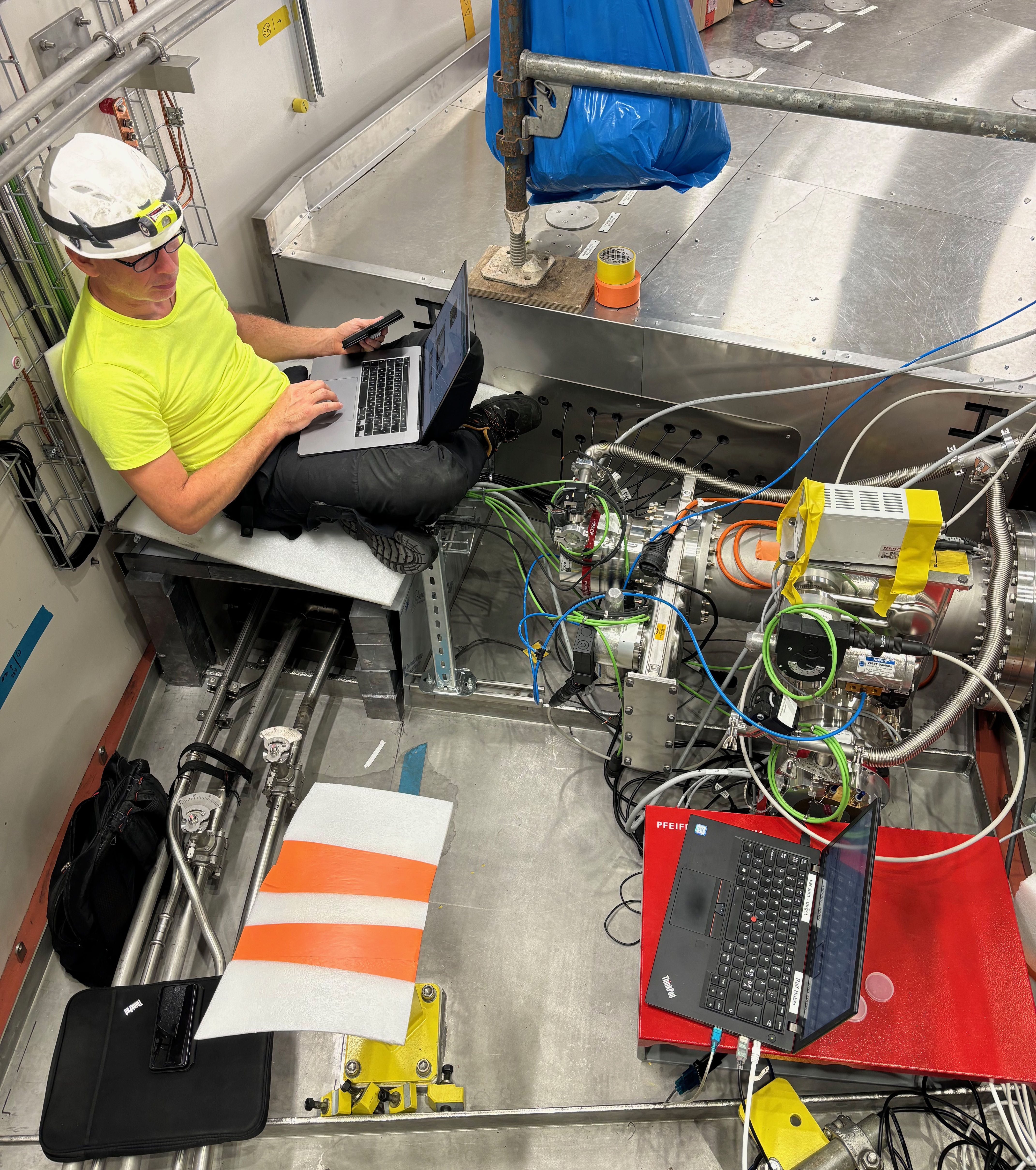

The target wheel rotation tests are being carried out by the ESS Integrated Control System (ICS) and Target Installation teams. Over the past few months, technicians from ESS's electrical contractor Actemium installed all the required cabling and powered the cabinets required for the target wheel commissioning.

The process is controlled through EPICS (ESS’s integrated control system platform), with most functionalities already in place. Additional features, such as the Target Safety System (TSS) and Machine Protection System (MPS), will be integrated gradually.