The installation and testing of all vacuum chambers and hardware for the ESS accelerator have been successfully completed. This achievement, which includes vital contributions from UK In-Kind Partner STFC Daresbury Lab, is critical for preparing the system to accelerate the proton beam through the accelerator and eventually land it in the tuning beam dump at the end of the tunnel.

The successful installation and testing of all vacuum chambers and hardware within the ESS accelerator system marks a significant milestone on the road to ESS Accelerator Commissioning.

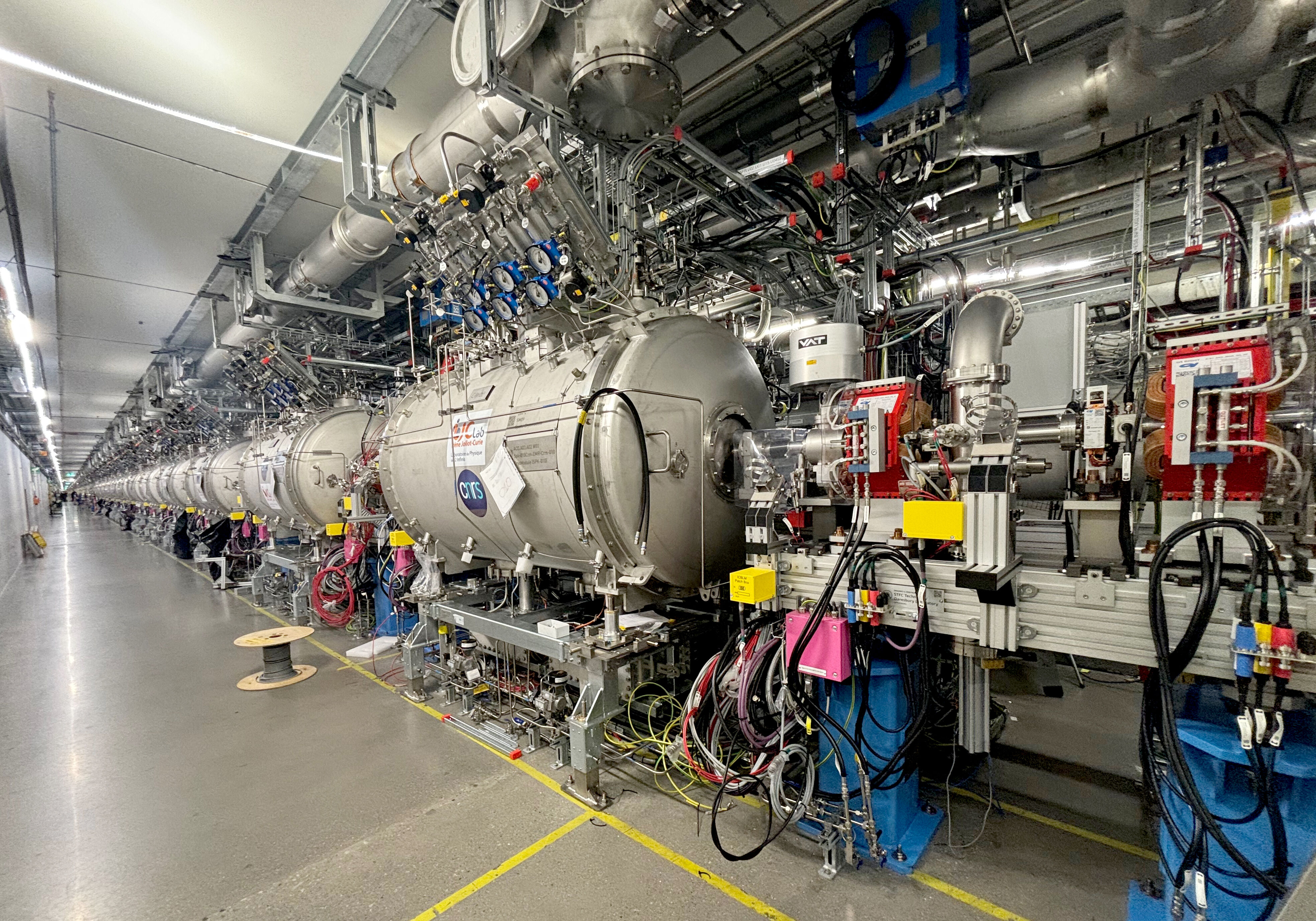

The vacuum envelope includes the entire system, from the ion source, through the superconducting linac, to the proton beam window chamber in the target station. This achievement is one of the critical milestones on the ESS Road to Accelerator Commissioning and the readiness to put Beam on Dump, i.e. accelerate beam through the accelerating structures and vacuum pipes and land it in the tuning beam dump at the end of the tunnel.

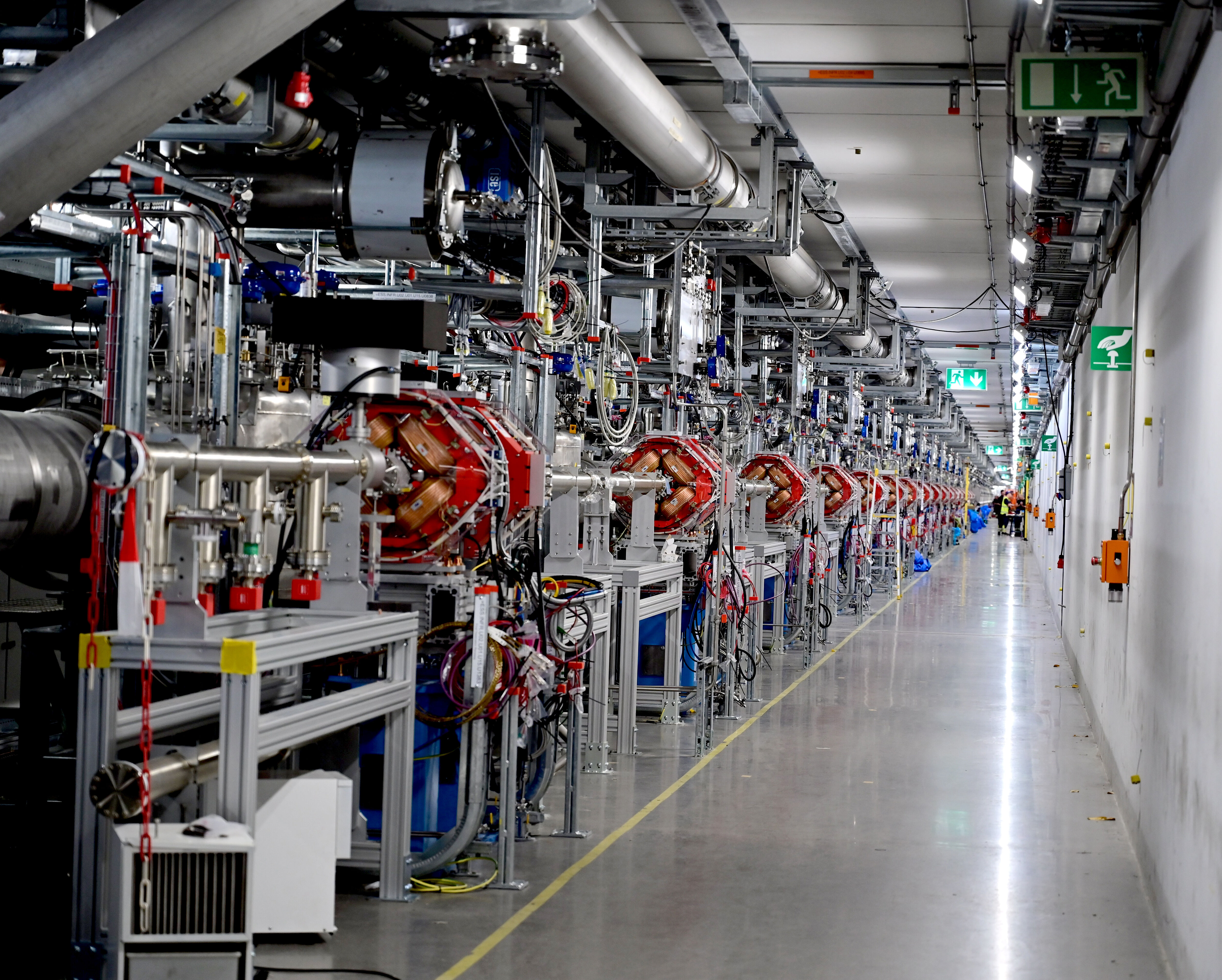

The ESS proton beam requires acceleration to 2 GeV of energy to achieve spallation at the target wheel. This is accomplished within a relatively short distance using Superconducting Radio-Frequency (SRF) cavities, which provide high-performance capabilities. To accelerate protons to near light-speed, the entire accelerator system is designed to operate under low gas density (vacuum) conditions. This vacuum environment extends across the linac, the monolith target vessel, and the Neutron Scattering Systems (NSS) instruments. Maintaining such a vacuum is critical because, at higher gas densities, proton beams encounter scattering, instabilities, and increased radiation levels, which could lead to electrical failures in high-gradient structures.

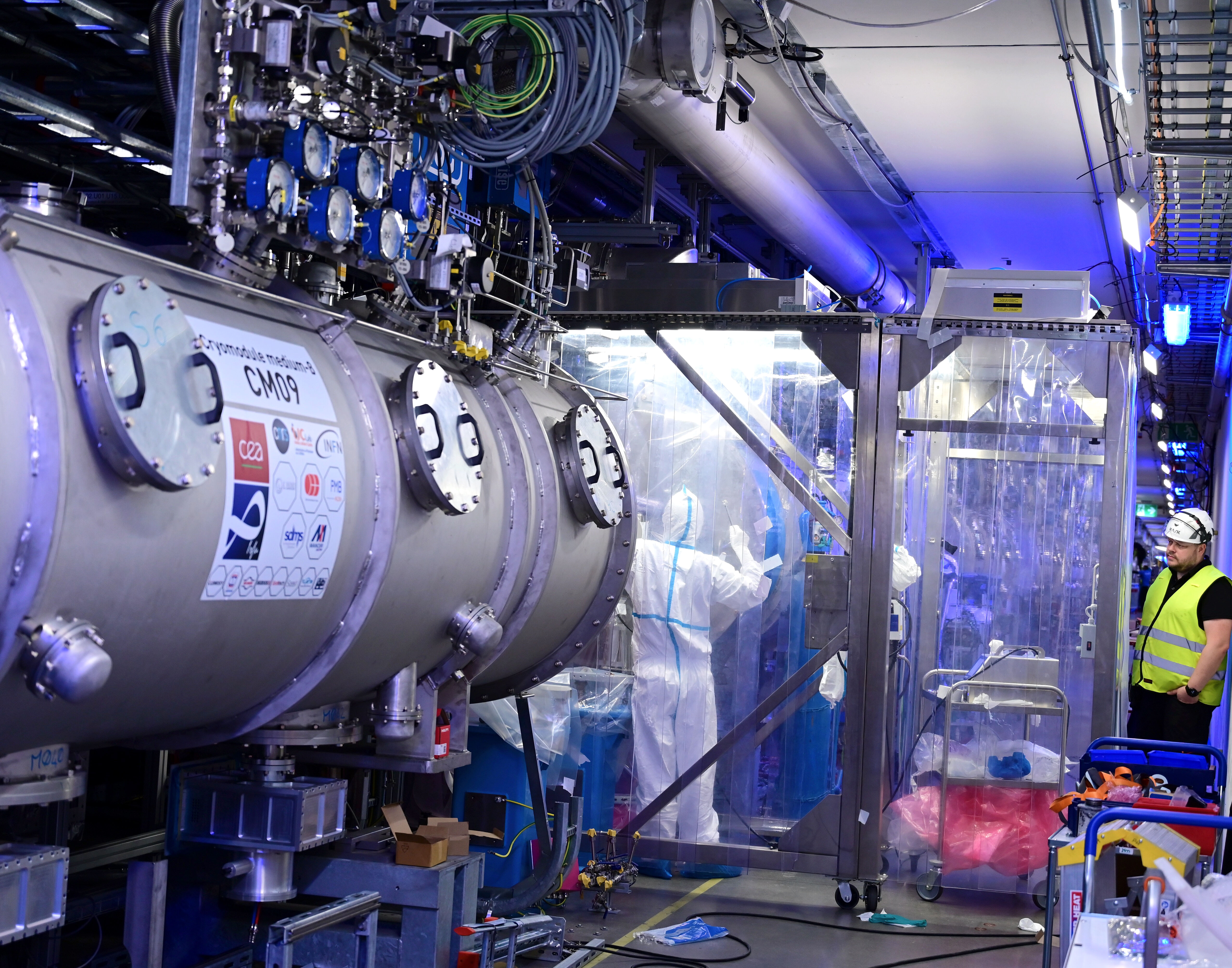

The vacuum system in the accelerator spans 600 metres and operates across a range of pressures, from 10⁻⁴ mbar at the start of the linac to as low as 10⁻¹¹ mbar within the SRF cavities, ensuring a "particle-free" environment with minimal contamination. The reliability of a vacuum system of this complexity is essential for maintaining optimal performance, and requires the employment of advanced technologies such as chemical pumps that operate without external connections and low-maintenance mechanical pumps with long warranties. The design also minimises the number of components and connections to reduce the risk of unscheduled downtime. With nearly 500 vacuum components and 1,000 connections in the linac, rigorous testing and proper acceptance procedures were conducted to ensure the quality and reliability of all parts.

The vacuum system is now ready for Beam on Dump (BOD), with preparations underway for the next phase: Beam on Target (BOT).

Acknowledgements go to the in-kind collaborators from the Vacuum Solution Group/ASTeC at STFC Daresbury Laboratory. Their contributions, particularly in the development of vacuum chambers and Linac Warm Units (LWUs) since 2014, have been vital to the successful completion of the accelerator vacuum project.

More updates from the ESS Accelerator, highlighting the road to beam commissioning:

- The Power to Accelerate: RF Power Stations up and running

- Installation and Testing of the 2 MW RF Scope Completed

- ESS Completes Installation of Beam Current Monitors in the Accelerator

- First Insertable Beam Stop installed in the ESS superconducting linac

- Magnets Ready to Focus and Steer the Proton Beam

- Warm Coupler Conditioning starts in the ESS Superconducting Linac