Talk of nuts and bolts turns literal as the ESS instruments project reaches 20% completion. The semi-annual collaboration meeting also marked significant steps forward in installation planning.

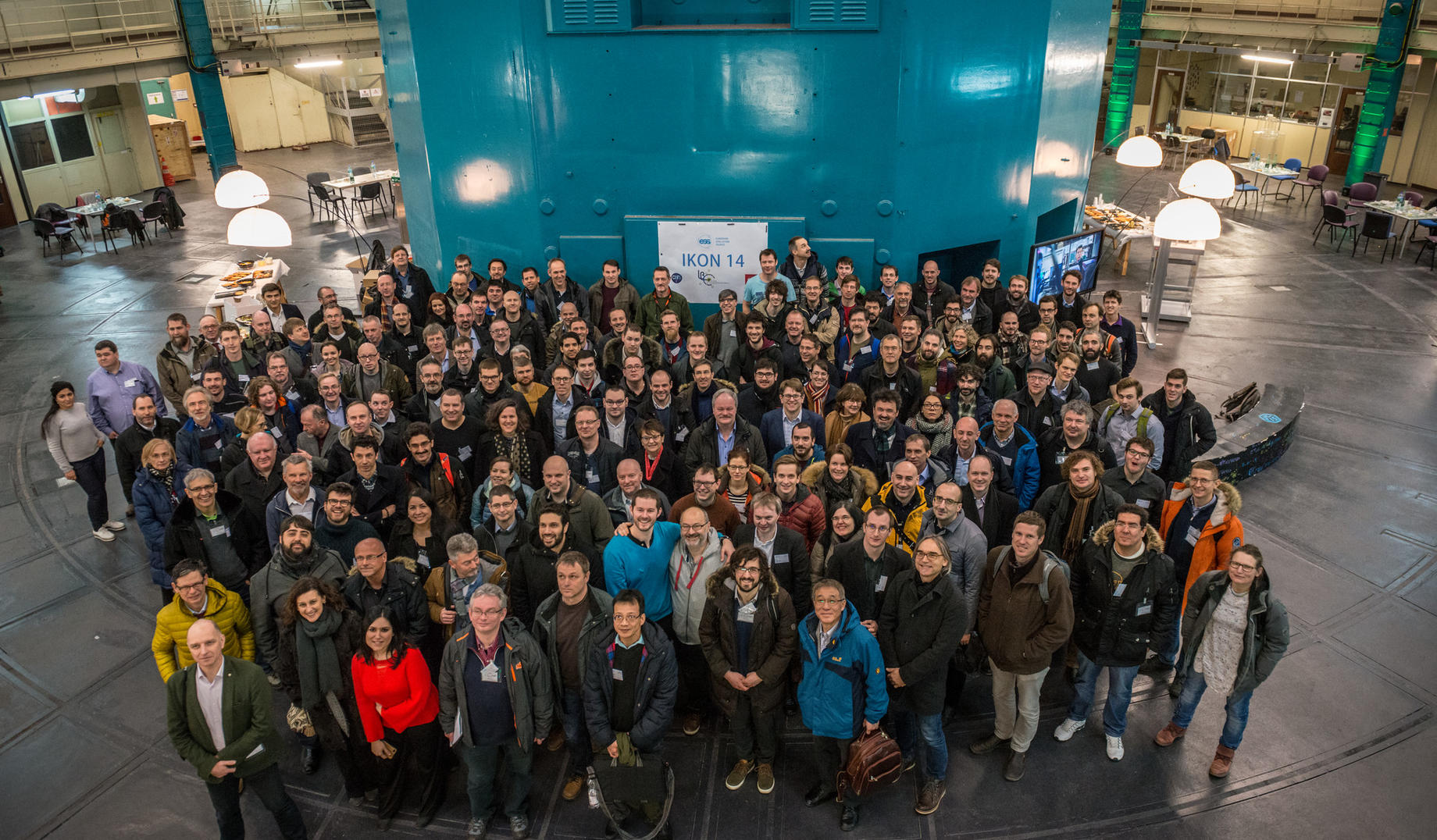

PARIS—Two-hundred contributors to the European Spallation Source (ESS) Neutron Scattering Systems (NSS) sub-project met near Paris last week for the 14th In-Kind Contributions Meeting for Neutron Science at ESS (IKON14). The three-day meeting was hosted jointly by ESS and French in-kind partner Laboratoire Léon Brillouin (LLB), one of the longstanding centres of gravity in European neutron science and a key in-kind partner for instrument construction at ESS.

Construction of the first 15 instruments stands near 20% complete, with all instruments having substantially completed a preliminary design review known as “Tollgate 2”. The meeting’s focus covered the integration of instrument schedules with the ongoing re-baselining of the larger ESS project schedule, and how to most efficiently meet the requirements of “Tollgate 3” (detailed engineering design) and “Tollgate 4” (installation readiness) in the staged process of instrument construction.

On the TGV to SOUP

In a detailed update of the ESS project, Director General John Womersley tuned the meeting’s focus to installation planning. Referencing recent installation milestones for the ESS Accelerator, including the ion source, cryogenics systems, and a temporary control room for LINAC commissioning, Womersley indicated that the instrument teams will greatly benefit from the experience of those who have come before them.

“In summary, there’s a huge amount going on. Every month you go out to the construction site you will see progress and new things happening. We’re on a moving train, the train is moving very fast,” said Womersley. “We need to adjust our circumstances to deal with issues as they arise, but all of our activities in the coming year are directed toward maintaining the momentum toward that famous serving of SOUP—the ‘Start of the User Program’. There’s a lot of serious work to be done underpinning this goal.“

Impact of Regulatory Changes Being Assessed

Uprated seismic and security requirements introduced in Sweden, and around the world, following the Fukushima earthquake resulted in a necessary re-engineering of some of the conventional facilities designs at ESS. This means that access by the instrument teams to the two smaller instrument halls will come later than hoped, while access to the large instrument hall, where eight instruments will be installed, remains more or less as anticipated. These so-called ‘E’ buildings will be made weather-tight before the year is out, with installation activities to begin late 2019.

The meeting’s general response to the shift in the civil construction schedule was to explore all possibilities to adjust activities within the NSS project, given that installation sequences are still very much in play. The outlook was enthusiastic.

“The high-level focus of this meeting was to find ways to minimise the impact of any changes to the schedule,” said ESS Science Director Andreas Schreyer. “While these will put pressure on the time available for hot commissioning they have no impact on our commitment to deliver 15 world-leading instruments for ESS. We are looking closely at a number of ways to mitigate the impact, using the many examples of peer projects that have faced the same issues and come out on top. What dominates these discussions, however, is the feeling of how exciting our project is.”

Partnerships Provide Efficiencies

Installation will be coordinated from the ESS side of the in-kind partnerships under the direction of NSS Project Leader Shane Kennedy and his team. Each instrument’s installation will require direct on-site supervision by its in-kind partners, and therefore success will rely heavily on the fundamentals of careful planning, cross-project coordination and communication.

“We have a very high level of confidence in our in-kind partners, and we are very happy to have all of you here putting your expertise toward ESS,” Kennedy told the IKON attendees.

Through its many collaborations, ESS is able to develop and integrate its systems at other facilities while civil construction continues at the site. Underscoring Womersley’s vision of tightening up installation processes through experience, Kennedy invoked recent results from integration tests using the ESS V20 test beamline, which is installed at Helmholtz-Zentrum Berlin’s BER II neutron source. The integration tests included the full spectrum of ESS inputs to the instruments project:

“We have recently had successful tests of integrated systems in Berlin, including detectors, choppers, DMSC [Data Management & Software Centre], and ICS [Integrated Control System], and we aim to continue those, increasing the team at the test beamline.”

Also serving to bolster iterative efficiencies across the project is another test beamline in operation at the Budapest Neutron Centre, which will be installed at ESS to commission Target Systems. It was highlighted at the meeting that this moderator test beamline will be the first beamline installation at ESS, providing key advance input for instrument installation to follow.

Tollgate 3: Workshops and Ad Hoc Meetings Put Instrument Engineers in the Room with ESS Technical Teams

The intense work to address the myriad issues of detailed engineering and installation planning, both of which will require expert coordination and management, took the form of several workshops and ad-hoc meetings between the instrument technologies groups from ESS and the instrument teams, which are mostly based at partner institutes.

All 15 instruments are moving into detailed engineering design, with some already well advanced. The IKON technical workshops enabled face-to-face clarification on specifications related to everything from how to connect an instrument’s electronics to DMSC, to which types of bolt heads should be used inside the ESS common shielding bunker.

For the first time, a satellite meeting was held by the ESS Detector Group and DMSC concerning their interfaces with the 15 instrument teams, adding a fourth day of workshops to the IKON proceedings.

A good part of IKON14 was dedicated to the ESS requirement that facility components adhere to European directives for CE marking, the formal application of a set of standards for functionality and safety. Implementing this strategy is an initiative of the ESS Quality Division.

“The value of CE marking is in the process and the documents produced, which ESS needs,” explained ESS Head of Quality Mattias Skafar. “The ultimate goal is safety, and the standard means that each partner does not have to define its own method.”

Tollgate 4: ‘It has to be ready, Ikea-style’

There are many challenging jobs at ESS, but one that stands out is Antonio Bianchi’s, which is to coordinate detailed on-site installation planning for the 15 instrument projects. Bianchi sits at the heart of the ESS in-kind process as the hub of a rapidly spinning wheel with spokes reaching out not only to every instrument in-kind partner and supplier, but to each construction sub-contractor, and nearly every engineering group within the beehive of ESS engineering groups. Still he exudes enthusiasm with each PowerPoint slide of to-be-completed schedules.

“Every little detail has to be accounted for—it has to be ready, Ikea-style,” jokes Bianchi, referencing the Swedish flat-pack furnishings behemoth. “It is very exciting for the project to enter this stage of instrument construction.”

In a blur of Gantt charts, tables and colourful diagrams, Bianchi spends each IKON meeting giving early warning to the instrument teams to supply him with the details required to coordinate such things as which tools will be needed when; where to store 300 cubic metres of concrete shielding blocks so they are convenient to access but not inconvenient to site operations; where to store the next 300 cubic metres of shielding blocks; how to schedule shipping for each instrument component of each instrument project so that none arrive too early, and none too late; and how to ensure that there is a Swedish-certified, English-speaking sub-contractor available to safely lift, move, access, weld, cut or assemble a given instrument component on a given day.

ESS in Saclay: ‘A revolution in neutron science’

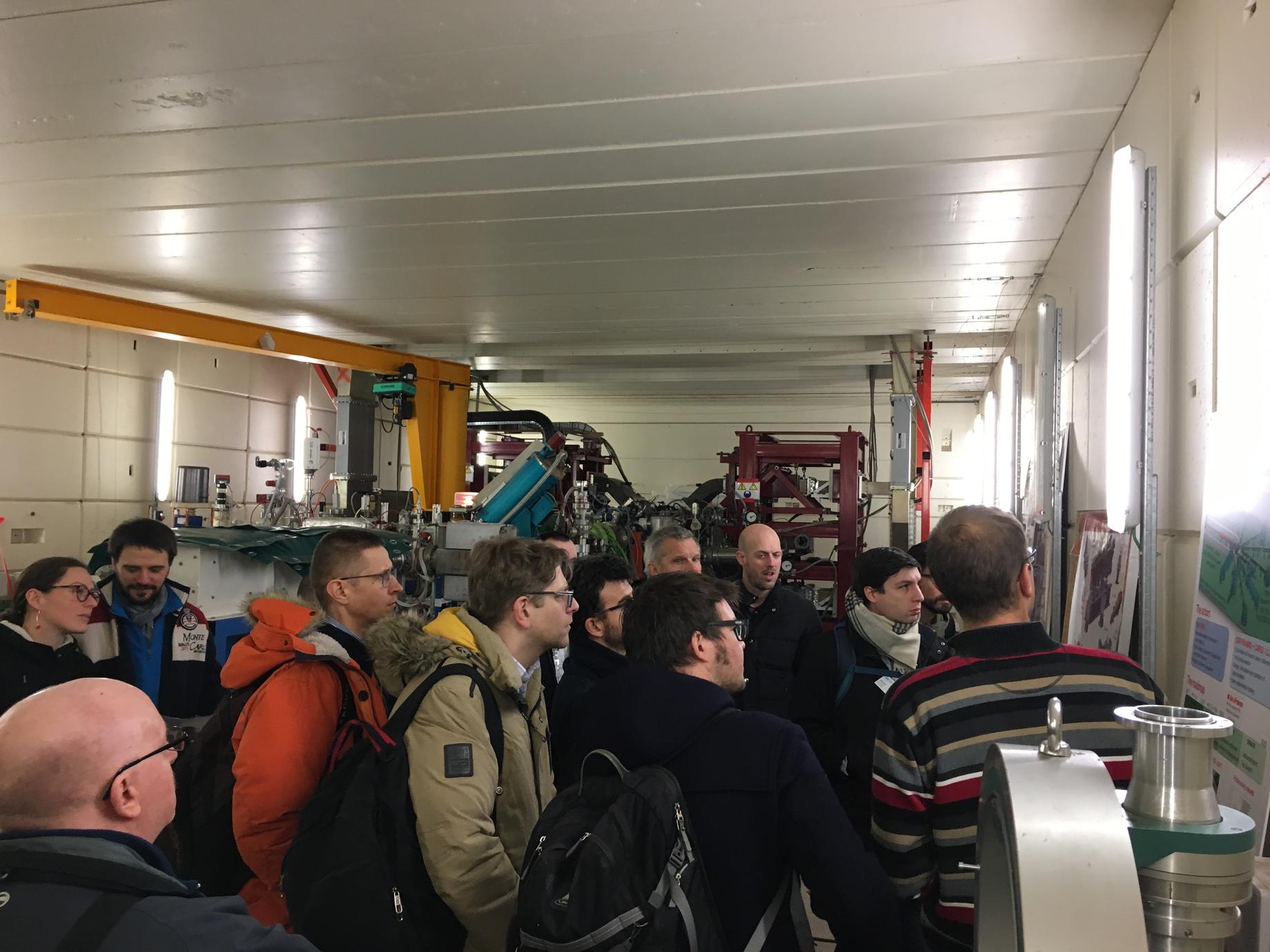

IKON14 attendees were treated by their LLB hosts to tours of some of the exceptional French national facilities on the Saclay plateau, including the 14 MW Orphée reactor dedicated to neutron science, and IRFU, the Institute of Research into the Fundamental Laws of the Universe, where there are multiple ongoing projects dedicated to the development and construction of the ESS Accelerator.

LLB is a partner on six of the first 15 instruments at ESS, and Deputy Director Eric Eliot opened the IKON14 proceedings by noting the central role of the lab’s in-kind contributions in the development of ESS. Eliot outlined a vision of the future collaboration between the two organisations, and how LLB’s high competence in neutron science will feed directly into the ESS user program.

“My main aim is to maintain the neutron science user community in France,” said Eliot as he described plans for a new compact neutron facility at LLB, the lab’s contributions to ESS, and LLB’s commitment to Europe’s flagship neutron science facility Institute Laue-Langevin. “With the new facility,” said Eliot, “we can prepare experiments for application at ESS. This is a revolution in the way of doing neutron science.”

IKON15 will be hosted by ESS in Lund this September.